82 Floor Repair (I need help) |

Post Reply

|

Page 123 4> |

| Author | |

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41040 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 82 Floor Repair (I need help) Topic: 82 Floor Repair (I need help)Posted: April-20-2007 at 5:00pm |

|

It is a general purpose thickener. You use it for making a paste with the epoxy that can be used for filleting or filling holes. Do not use it for fairing as it is not the easyest to sand.

|

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-20-2007 at 4:38pm Posted: April-20-2007 at 4:38pm |

|

What was I supposed to do with the Aerosil-Cabosil thickening agent?

|

|

|

|

farmer

Senior Member

Joined: July-23-2006 Location: United States Status: Offline Points: 442 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-07-2007 at 8:37am Posted: April-07-2007 at 8:37am |

|

west systems has some good instructional guides. Their "Fiberglass boat repair and maintenance" 002-550 goes into stringer repair among other things. |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41040 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-07-2007 at 6:56am Posted: April-07-2007 at 6:56am |

|

I've lucky to have my garage shop heated except for the $ but no A/C. Last summer when the heat finally penetrated through the slab, I put my box fan in the door from the A/C'd house to the garage. Worked damn good!! Didn't seem to overburden the house A/C but We don't get the "Texas" heat and humidity up here.

|

|

|

|

Bob's2001

Senior Member

Joined: March-28-2005 Location: Lake Jackson TX Status: Offline Points: 241 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-07-2007 at 1:14am Posted: April-07-2007 at 1:14am |

|

Jon, wait til Monday & it will be warmer. It's going to be a miserable weekend in Texas, so I worked on my stringers til nearly dark and put her up til next week. I can't get mine in the garage to work on it, too much stuff. The garage WOULD be big enough if I cleaned it out, but still no heat. I wish for A/C most of the time.

|

|

|

Bob Ed

83 2001 |

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 3:44pm Posted: April-06-2007 at 3:44pm |

|

Pete,

You dont know how bad I would like to have heat in the garage. The boat is actually in a barn and right now I am working with 200ft of extension cord just to have a trebble light and one electric power tool(more than that and it will throw the reset on the outlet). Brian, Skibum and Eric's and info from this thread are all that I have used so far. They are great and without them I would be totally lost. The problem is they are just not detailed enough, I am completly new to working on boats and fiberglass and need baby steps. When I am done with this project I owe correctcraftfan.com a major donation. Because without it I would have had to spend twice what I am to get this done by someone else. |

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 3:04pm Posted: April-06-2007 at 3:04pm |

|

I wouldn't say I've found a good book. However, taking bits and pieces from a couple, I'm getting a better picture.

These books are written by guys that have done this type of work for many years, which is good. On the other hand, they are not "authors" by trade. Accordingly, a lot of the text is not so easy to follow. DavidF referred me to a book called The Fiberglass Boat Repair Manual by Allan H. Vaitses. It dicusses materials and application well, but much of the text is geered toward fixing big sail boats. He also referred me to a DVD called Fiberglass Repair by Will Borden. I thought it was best for showing application of gel coat. I picked up another white paper type book which is not sitting in front of me, but it was geared toward bass boats. None of these books were as desciptive about the application of the fiberglass specific to stringers as I would have liked. Actually, if you follow the two threads by SkiBum, he's just about text book. No doubt he was a little more zealous about fairing and building a smooth bildge than the experts, but his bildge does look great. The one thing I am still not clear about: Once you have put the stringer in place, in a bed of mat, and let it dry, how do you apply the glass from the hull of the boat up the side of the stringer. The bass boat guy applied tow layer of mat to the sides of the stringers before he put the stringer in. Ski Bum appears to have used a lot of overlapping 4 inch strips up the side. I'm just not sure. BKH |

|

|

Livin' the Dream

|

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 2:55pm Posted: April-06-2007 at 2:55pm |

|

Have you found a good book? I would be interested so that I didnt have to annoy everyone on here every time I have trouble.

|

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 12:27pm Posted: April-06-2007 at 12:27pm |

|

Jon,

I've been reading some books on stringer replacement. All recommend two layers of mat, the same width as your stringer, as a bed. Than use filling compound to take up any gaps where you stringer is not perfectly contoured to your boat. BKH |

|

|

Livin' the Dream

|

|

|

|

farmer

Senior Member

Joined: July-23-2006 Location: United States Status: Offline Points: 442 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 12:04pm Posted: April-06-2007 at 12:04pm |

|

I've been keeping my garage at 55F or above and the west systems 205 fast hardener sets up well. I wouldn't try to go much below that.If you are unsure, get some small quantities of whatever brand you are going to use try it in small amounts. Farmer |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41040 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 11:43am Posted: April-06-2007 at 11:43am |

|

Jon, Get some heat in the garage!!

|

|

|

|

The Lake

Platinum Member

Joined: May-13-2005 Location: Lk Winnebago MO Status: Offline Points: 1157 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 11:11am Posted: April-06-2007 at 11:11am |

|

Jon,

I have done only a little fiberglass work, but I think the temp needs to be a lot closer to 80 than 30. The stuff will take forever to kick otherwise. Chuck |

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 10:41am Posted: April-06-2007 at 10:41am |

|

Pete, I think that is a great idea.

What do you think about the temp? |

|

|

|

75 Tique

Grand Poobah

Joined: August-12-2004 Location: Seven Lakes, NC Status: Offline Points: 6107 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 10:35am Posted: April-06-2007 at 10:35am |

Tim, So you've taken delivery on your Tique. Either I missed that or you haven't mentioned it on here. When did you get it? Obviously the delivery went fine. Sounds like you're tearing right into it. Any surprises? How is it looking? I'm trying to remember the engine situation...weren't you looking for a new engine to put into it? Larry |

|

|

_____________

“So, how was your weekend?” “Well, let me see…sun burn, stiff neck, screwed up back, assorted aches and pains….yup, my weekend was great, thanks for asking.” |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41040 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 10:25am Posted: April-06-2007 at 10:25am |

|

Jon, I would say a layer of mat the width of and under the stringers would be helpful especially with sealing the bottom edge of the wood stringer. (lay the stringers into the mat with resin before it starts to set up) Bill (skibum) recommends this as well since it will even out any minor irregularities.

|

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21131 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 10:20am Posted: April-06-2007 at 10:20am |

|

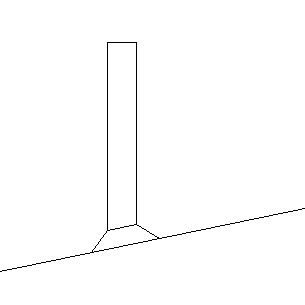

I dont believe you want the stringer to actually touch the hull. Ive read that there should be something to bed the stringer- I think SkiBum used fiberglass. Ive read of people simply placing a strip of foam under the stringer- I think this is what CC does (or at least used to do) at the factory. I actually pulled some foam out from under the stringer on my Ski Tique. I suppose most anything to create some space between the wood and hull would be fine and would prevent creating any hot spots. If you can put a chamfer on it, it will be easier to lay the glass too. Something like this:

I cant remember the recommended thickness of the bed, but Id guess 1/8"-1/4". |

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-06-2007 at 9:55am Posted: April-06-2007 at 9:55am |

|

Eric, I will definetly give you a call if I need help.

I have my stringer all made and ready to install and now it is 30 degrees outside. My boat is inside but not heated and I am afraid that at that temp. the epoxy would never sit up. My stringer fits really tight to the bottom of the boat. Do I need to lay mat under the stringers or just epoxy them strait to the floor?? |

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-04-2007 at 9:27am Posted: April-04-2007 at 9:27am |

|

I heard one guy on wakeworld say $3000.

It looks like I am going to spend at least $1,000-1,200 doing it myself. |

|

|

|

dbrown

Newbie

Joined: August-23-2006 Location: United States Status: Offline Points: 5 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-03-2007 at 6:33pm Posted: April-03-2007 at 6:33pm |

|

Has anyone had their floor and stringers professionally replaced? If so, what are we talking is a ballpark for having the repairs done? Problem is, I live in the Chicagoland area and I am tapped for space. I would have to most likely outsource the project.

|

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-03-2007 at 5:24pm Posted: April-03-2007 at 5:24pm |

|

Good luck, if you run into a snag you can give me a buzz, 330-322-8817 or 330-995-4037

It really is simplier than you think, just use common sense and anything you do to reinforce the boat will be better than it has been (rotted) its probably been rotted for years and the boat hasnt cracked in half yet. one of the main reasons for those stringers are to mount your engine, the hull itself is very rigid. Eric |

|

|

"the things you own will start to own you"

|

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-03-2007 at 4:08pm Posted: April-03-2007 at 4:08pm |

|

Tonight I am going to start doing something productive and not just tearing stuff up.

Bill, Eric, Pete or anyone that has done this before, will you give me a step by step guide of how to epoxy and install the stringers. Remember you can not make it to stupid for me. At this point the only thing I know about fiberglass is it is really itchy and dusty when grinded. I hope to get the first secondary stringer shaped tonight. |

|

|

|

farmer

Senior Member

Joined: July-23-2006 Location: United States Status: Offline Points: 442 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-18-2007 at 7:21pm Posted: March-18-2007 at 7:21pm |

|

Jon,west system has two different fairing additives.407 Low-density filler and 410 Microlight.Either one can be used,and although the 410 is a little easier to sand it cannot be used on topsides or under dark colors because of temperature issues. I've found a supplier that I'm very happy with.They are Ward Marine (www.wardmarine.com) in Mass. Very competitive pricing and great to deal with. Farmer |

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-17-2007 at 9:38am Posted: March-17-2007 at 9:38am |

|

Thank you. BKH

|

|

|

Livin' the Dream

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41040 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-17-2007 at 7:53am Posted: March-17-2007 at 7:53am |

|

bk, All fillers come separate. You start with the base resin and then and then add the filler. The type of filler depends on what you are doing with it. In general, The stronger the filler the harder it is to sand so the stronger ones are used for structural and the first coat fileting.

Jon, Keep in mind that Bill was going for a glass smooth finish in his bilge that you really don't need so the fairing may not be needed. If you look at his pictures, you'll see that his bilge looks better than the outside of a Mastercraft!!! |

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 8:31pm Posted: March-16-2007 at 8:31pm |

|

Bill, question? Does the 403/404 come premixed, or do you need to add the fibers into resin? BKH

|

|

|

Livin' the Dream

|

|

|

|

SkiBum

Gold Member

Joined: November-17-2006 Location: United States Status: Offline Points: 587 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 8:01pm Posted: March-16-2007 at 8:01pm |

|

Therea are a variety of fillers you can use for reinforcing, fairing, or thickening your resin. The most basic filler is talc. It is also very inexpensive. Fairing compounds can be made from talc, tiny glass bubbles, or a combination of compounds. They are available from US Composites and West Marine (more places as well-I just know of these two sources).

After I glassed in the stringers I used West 403 Micro Fibers to make a thick bead along the joint. It extended up the stringer about one inch and onto the hull one inch and it was 1/4" to 3/8" thick. I learned later I should have used West 404 filler instead. This was because the 403 is cotton and the 404 is glass which adds more strength. The use of this filler was to keep the 50-50 ratio of resin and glass for strength while bedding the stringer. When the glass work was finished there were uneven spots, layers, and print along the stringer and hull. I used fairing compound mixed with resin to fill the voids and create a flat surface. Another use for the fairing compound was when I finished glassing the floor. There were small depressions throughout. I spread the compound on the entire floor and it filled the low spots and created a very even and flat floor. I thickened some compound and put a small bead along the side of the hull and floor to increase runoff. You can use fairing compound to level, fill, and shape your work. |

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 5:49pm Posted: March-16-2007 at 5:49pm |

|

Fairing compound is for fairing - to make smooth, or aerodynamic. I believe the term comes out of aeronautics, but I'm not sure. This is why it is called a fairing on a motorcycle.

Bondo is a common fairing compound you are probably familiar with. You apply the compound and sand off to provide a smooth surface. In this case, the fairing compound is being used to form a smooth, arced surface between the right angles of your hull and the stringer. Fiberglass has trouble making a crisp 90 degree turn. By using some fairing compound to create an arched surface, you provide a rounded surface to make the transition, and avoid air gaps under the fiberglass when making the 90 degree turn. In this case, the fairing compound is resin with a thickening substance mixed in so that you can work with it and shape it. BKH |

|

|

Livin' the Dream

|

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 5:26pm Posted: March-16-2007 at 5:26pm |

|

I am putting my order together and have a questions?

What is fairing compound, where do I find it and what do I use it for?? |

|

|

|

jon4pres

Senior Member

Joined: September-19-2005 Location: United States Status: Offline Points: 275 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 11:11am Posted: March-16-2007 at 11:11am |

|

Pete, I will try to take some pictures this weekend. They are pretty sad though.

|

|

|

|

scott8370

Gold Member

Joined: November-30-2005 Location: United States Status: Offline Points: 872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-16-2007 at 10:36am Posted: March-16-2007 at 10:36am |

|

Bill, your so right.I held off on my post for a couple days for that reason. There are many ways of doing a job right. And most of the four pages of techniques will get the job done

. .

|

|

|

Scott

|

|

|

|

Post Reply

|

Page 123 4> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |