Stringer Replacement 86 Silver Nautique.

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=50958

Printed Date: April-30-2025 at 11:25am

Topic: Stringer Replacement 86 Silver Nautique.

Posted By: andrewmarani

Subject: Stringer Replacement 86 Silver Nautique.

Date Posted: October-21-2022 at 4:12pm

|

Finally pulled the trigger on replacing the stringers on our Silver Nautique, been on the list for a decade. I will post pictures over the winter, with the ambitious schedule to be done by late spring for skiing. Over the weekend I pulled the seats and vinyl, dropped the rudder, pulled the shaft, removed the gas tank and other misc. stuff. Had our boat mechanic pull the engine and store it. Best $200 I’ve spent in a long time. He thinks the motor is in good shape but will do a general review and a cylinder compression check while he has it. My plan is to hang the boat to pick up most of the weight. I’m also going to put supports under the two back corners and one support centered up front, just before the flat spot ends under the boat (just a bit in front of the fins) to keep things still while we work. Those supports will also help me level the boat for the glass work. I’ve been reviewing stringer materials and, of course, recommendations are all over the place. I don’t think the bottom of the boat is really designed to flex, fiberglass is pretty rigid in plane and flexing the string encasements would crack them. So I’m not worried about picking something flexible for the stringers. My second choice is white oak: strong, stiff, highly rot resistant and not very expensive. But oak is not dimensionally stable, it will expand and shrink a bit depending on moisture. Yep, theoretically no moisture should get in there but, well, stuff happens… Same stability issue exists with most other solid wood choices (Douglas fir, etc.) My current first choice is Marine Ply, laminated together to get the right thickness, with staggered joints. Will be stiff, soaks up penetrating epoxy well (unlike oak) to make it more rot resistant and is dimensionally stable moisture wise. Forum thoughts on this are welcome. ------------- Builder |

Replies:

Posted By: andrewmarani

Date Posted: October-23-2022 at 9:47pm

|

Hung the boat from the lifting rings today. Braced in the back corners and either side of the center just in front of the fins and drove some thin shims between the hull and the supports to take a touch of load off of the lifting rings. Easy enough to level it side to side. Front to back was harder since nothing seems to match. Decided to make the floor level, which put the existing aluminum engine support slightly out of level front to back compared to the floor but I doubt that matters much.

------------- Builder |

Posted By: andrewmarani

Date Posted: October-26-2022 at 10:31pm

|

Deconstruction currently held up by the pylon. I searched but couldn’t find any specific directions to remove the pylon beyond pulling the stainless bolt that goes through the bronze fitting at the hull and knocking out the lower pin that goes through the base of the pylon and tapping the pylon up with a hammer on a wooden block through the ring. Not working, even though the pylon moves just at touch on the steel pin that connects the pylon to the bronze fitting. Picture below. Love to talk to the dude who though it a good idea to tie a bronze fitting to an aluminum post with a steel rod. My next move is to put a post on either side of the boat, run a beam over them and put significant upward tension on the ring with a come along, heat the base of the pylon and tap up on the ring with a block of wood and a mall. Any other ideas are welcome. After tapping up on the pylon I noticed a touch of moisture around the base of the bronze fitting at the fiberglass hull which I don’t think was there before. So I’m likely going to need to grind down around the fitting, see what’s going on and fiberglass things back together. Anyone know exactly how the bronze fitting is set into the hull? Picture below, but tough to see the moisture.

------------- Builder |

Posted By: gun-driver

Date Posted: October-29-2022 at 10:18am

|

Soak it with a 50/50 mix of acetone & tranny fluid. Let it soak for a couple days reapplying and tapping with a hammer daily. Then heat the brass socket to draw the fluid in… squirt, tap, heat and repeat. Good luck 👍

|

Posted By: andrewmarani

Date Posted: October-29-2022 at 10:20am

|

Well that was a total fail. I put enough upward pressure on the pylon to lift the boat slightly off the chocks in the front, put some ice around the bronze fitting to keep the fiberglass cool and heated the base of the pylon to 250 degrees. Used a piece of wood and a mall to hit upward on the ring and got nothing. So looks like the pylon stays in during the repair. I will, hopefully, be able to remove the ring later today so I can slide the aluminum motor cradle off the pylon and get it out of the boat. ------------- Builder |

Posted By: TRBenj

Date Posted: October-29-2022 at 10:57am

|

Need to twist it to break it free. Get it good and lubed up first, and get a couple heat cycles on it. Small pry bar through the ring and finger (protected by a rag) should do it. Can’t imagine doing a stringer job without it out of the way. |

Posted By: gun-driver

Date Posted: October-30-2022 at 9:58am

What Tim said but just be very careful when twisting from the ring finger, it will bend if you apply to much pressure. You may be better off getting a big pipe wrench and twisting from the bottom.

|

Posted By: andrewmarani

Date Posted: October-31-2022 at 9:46am

Removed most of the fiberglass flooring plus all the foam under the front deck over the weekend. I don't think i'm going to reinstall the hump under the front deck, just going to run the flooring through flat. i've got some mahogany laying around from an old bleacher tear out we did, I can make a foot rest from that and attach it to the floor. Don't see any real need for that hump full of foam. Boat has been out of the water and under cover for 2 months but bottom 2" of foam was still soaked. ------------- Builder |

Posted By: gun-driver

Date Posted: October-31-2022 at 6:44pm

|

Now you should be able to get a big pipe wrench on the bottom of the pylon. Since I already did a complete gut and stringer job on my ‘85 I would suggest only tearing one side out at a time. It’s a whole lot easier getting your heights and measurements when you can mirror the other original side. JMHO

|

Posted By: andrewmarani

Date Posted: November-05-2022 at 6:52pm

|

Used a diamond blade on a grinder to cut the rest of the flooring back right next to the sides, worked pretty well. Holding a vacuum in front of the blade kept any dust to a minimum. Then removed all of the foam. Just for fun I weighed the bags of old wet foam, came up to 155 lbs, which is less than I expected. Next steps are to use a sander to remove most of the old carpet glue on the sides of the boat. Then mark a line 12" above the current floor location so I can locate the floor after I grind the last of the floor fiberglass off of the sides. After that I will make a drawing of the secondary and primary stringers so I don't lose any information. Then (following gun-driver's suggestion) cut out and rebuild one side of stringers. I was planing to use marine ply for the stringers but finally looked up Coosa Board after seeing referenced often and realized that it's not wood but a stiff composite, so planning to head in that direction instead. Also spending time thinking about a deck material, anyone familiar with Nidaplast-8? Seems like 3/8" or 1/2" would make an excellent base material for the deck.  ------------- Builder |

Posted By: Wilhelm Hertzog

Date Posted: November-06-2022 at 2:18am

|

My boat's floor is made from Nidacore/Nidaplast. Only drawback in my experience is that it doesn't hold screws very well. I've had to create some epoxy plugs in the floor to give screws that experience high loads something to better bite into. ------------- 1982 Ski Nautique PCM351W RR II Velvet Drive 10-17-003 1:1 II PerfectPass Stargazer Do not go gentle into that good night. Rage, rage against the dying of the light. |

Posted By: andrewmarani

Date Posted: November-06-2022 at 8:43pm

|

Excellent! I need to find a local source for Coosa and the Nidaplast. There's only a couple of floor fastener locations, I may just glue some treated 2x under the Nidaplast at those locations. Sanded the old glue off the sides with a palm sander and 80 grit paper today. That went pretty easy, though I didn’t try and remove every bit of old glue since the fiberglass was pretty rough and removing all the glue would have removed a significant amount of glass. to locate the new floor, I drew a line 8” above the old floor onto the sides of the boat, then checked that with a level front to back and from side to side. It was close but a bit out in every direction, especially under the bow. Basically, the old floor wasn’t really flat or level in either direction. Since that’s how I originally leveled the boat, I decided to back up and check the stringers against the top of the boat sides. They were close but didn’t actually match level wise, not really surprised at this point. Since I can’t tell which are actually true to the bottom of the boat and they were close, I used the tops of the boat sides to re-leveled the boat side to side. Secondary stringers ended up about a ¼” out of level to each other with sides perfectly level, easily close enough for this project. Still needed a way to level the new floor so I pulled a string line down the center of the boat, bow to stern, and set it roughly 8” above where the old floor was. Then I leveled the string front to back. Laying a straight edge side to side across the secondary stringers and measuring up to the string, I had 8” at every stringer point I checked. I leveled from the string to the sides of the boat and put marks about every foot, used a short flexible straight edge to draw a line between marks from the stern all the way to the front hanger point under the bow. End result is a level reference line on the sides of the boat to locate the floor and the tops of all the stringers. Next up is grinding the remains of the old floor off the sides of the boat, planning to use a coarse flapper wheel and that’s likely to be ugly dust wise. Need a vacuum shroud for the grinder or a wide pickup for the vacuum. ------------- Builder |

Posted By: gun-driver

Date Posted: November-06-2022 at 10:33pm

|

Don't waste your time with flappers get these. https://www.amazon.com/Fibre-Disc-Aluminum-Oxide-Diameter/dp/B001HBUM5O" rel="nofollow - https://www.amazon.com/Fibre-Disc-Aluminum-Oxide-Diameter/dp/B001HBUM5O I buy mine at a local autobody supply. (I try never to buy from Amazon)JMHO

|

Posted By: andrewmarani

Date Posted: November-12-2022 at 5:09pm

|

Away for the weekend, looking over pictures and making plans. Realized that I didn't take three dimensions before I started the tear out. Can anyone with a Sliver Nautique send me the following dimensions? pylon to base of observer's seat. pylon to inside edge of battery box. pylon to base of driver's seat. Thanks Andrew ------------- Builder |

Posted By: andrewmarani

Date Posted: November-21-2022 at 8:46pm

|

Sides of the boat are mostly prepped for glass to attach the floor. This weekend I removed almost all of the stringers, still have the bottom inch or so of the main stringers to get out and a lot of grinding and sanding to do on the bottom of the hull. The secondary stringer came out pretty much intact with just some rot in the tops so I can use them as templates. The main stringers are attached hard to the bottom of the boat. Probably going to need to splinter the rest out with a hammer and chisel. Tops of the main stringers were trashed with rot. I was able to create a detailed layout of the old stringers on paper so I went ahead and removed both sides. I cut one side of the stringer fiberglass about 1” above the bottom of the boat to leave a lip and cut the other side flush with the bottom. I will use the lip to locate the new stringers and I’m planning to use one of the 3M adhesive caulks to attach the stringer to the bottom of the boat and hold it still while I wrap them in glass. Figuring the depth of the cuts in the stringer for the layout went a lot easier when it occurred to me to use one of the small laser levels we use on jobsites. Set it on the 8” line I’ve already established, which was pretty accurate with the laser level, and then measured down to the stringer at each elevation change. Also pulled the windshield. I need to repair the blocking under the deck so the screws will take up, find a gasket to put between the deck and the windshield so we stop taking water when one of the kids buries the bow in the wake looping to pick someone up. And find someone to powder coat the metal.

------------- Builder |

Posted By: andrewmarani

Date Posted: November-21-2022 at 8:59pm

|

Looks like some people put the foam back in and some leave it out. I lean towards leaving it out, less work and less weight. Anyone want to weigh in on the pros and cons? Other than the boat will sink if it fills with water. Don't think it would float anyway, there's not enough foam to offset weight of the engine, the hull and the other steel, aluminum, bronze items plus beer and sand. Boat weight 2300 lbs / 62 lbs per cubic foot for water = 38 cf of foam, pretty sure I didn't remove that much foam. ------------- Builder |

Posted By: KENO

Date Posted: November-22-2022 at 7:02am

|

No foam .....it's like a submarine sitting on the bottom With foam....it's still like a submarine but it's at periscope depth hovering up near the surface where you can still see it  Otherwise I don't have an opinion for you PS your boat weighs a lot less when it's underwater so your foam requirement would be different

|

Posted By: TRBenj

Date Posted: November-22-2022 at 7:47am

A little far along to be just starting to thing about rebuild strategies! If you eliminate foam (which I would also recommend), you should consider replacing the strength of the foam with additional structural members. It also affects your options for flooring, floor height, etc. Obviously it’ll affect material lists as well. |

Posted By: GottaSki

Date Posted: November-22-2022 at 8:06am

|

Indeed, that math didn't factor displacement early ski supreme before they went to composite in 86 had 4"x4"x8' foam strips in the lower hull, fastened to the hull with little straps of glass. not cavity-filled, so they see some air and have a chance to dry out. . Hence some pool noodle solution some have used.

There is also more foam higher up, inside each inner gunnel that wraps to the floor. these stay very dry over the decades.. and the bow is filled with foam. This all together met level flotation requirements at the time and makes the boat recoverable, without accumulating much water weight/ bloating over the years. Consider some of those techniques if your want the boat to be at least recoverable if things go awry and wont have to search yellow pages for scuba  ------------- "There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing." River Rat to Mole |

Posted By: andrewmarani

Date Posted: November-22-2022 at 10:52am

|

All good points. Hadn't considered the decrease in weight as the boat sinks. I would say that short of a catastrophic event I can't imagine the boat sinking, but there was that one time years ago when we forgot the plug. Somehow my youngest son heard the sound of water over the engine noise as he pulled away from the ramp and opened the engine cover to see a fountain... Now his first question is always "Dad, did you put in the plug?", not sure why that's my job!

I was wondering if there was a structural component to the foam but that seems like a bad way to design a boat hull. I can easily add a couple of stiffeners running perpendicular to the stringers. Probably just from the secondaries to the sides of the boat, which is were most of the foam was anyway. The bow was full of foam but the curvature of the fiberglas hull in that area adds strength above just the thickness of the fiberglass. I will leave the floor elevation where it was, don't see any need to change. Noodles?! that's an odd and interesting idea. Lightweight closed cell foam, loose so water can drain around them. Easy enough to calculate the cubic footage that will fit in the available spaces. I will play around with the volume of the various solid parts of the boat and try to come up with a displacement number and see if noodles could float the boat at periscope depth. Anyone ever see or hear of a sunken ski nautique? ------------- Builder |

Posted By: Riley

Date Posted: November-22-2022 at 1:43pm

| What happened to the pool noodles for flotation in the early days of CCF? How did those boats work out? There were a few people that tried it. |

Posted By: Gary S

Date Posted: November-22-2022 at 5:44pm

|

They sank Bruce taking their captains with them. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: KENO

Date Posted: November-22-2022 at 6:16pm

|

While you're noodling over what you're gonna do, here's a link to some CCF threads about using pool noodles for flotation  Like everything else you'll get differing opinions and all noodles aren't created equal either I'd figure.

|

Posted By: Tomrupp

Date Posted: November-23-2022 at 10:32am

|

I like the star shaped large noodles from Wally World. Don’t do the wrapped model because they get waterlogged. You might end up listing and get swamped by a wake boat swell. ------------- Tom 94 Ski Nautique Open Bow 351 with Carb 95 Double Decker Aqua Patio with 50hp Honda (3 carbs). |

Posted By: andrewmarani

Date Posted: November-23-2022 at 1:37pm

|

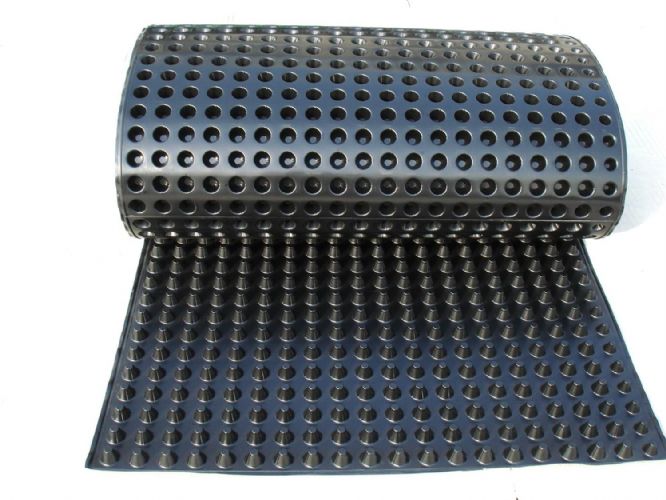

Ok, no noodles. After reading lots of posts, foam is back in the project. Sound dampening was a large driver in my decision. Since I'm planning to use a composite board for the floor I don't need the foam for any significant support so 2 lbs foam should be fine and gives minimal weight gain. Various posts discussed concerns about trapping water somewhere under/around the foam which I was worried about as well. In construction we use a plastic drainage board to eliminate hydraulic pressure against below grade walls, should work here to allow water to drain from under the foam. See the picture below, install dimple side down, pour the foam on top, put drain holes through the base of the stringers into the bilge. Still thinking this through, the drainage board could just move the trapped water up between the foam and drainage board. Also seems like there is just no place for water to be trapped in a fully foamed compartment...  ------------- Builder |

Posted By: uk1979

Date Posted: November-24-2022 at 9:29am

|

I have played around with foam in the hull... I went with lining the area with DPC (Damp Proof Course Polythene) leaving plenty

running over the sides to fold over the top to seal up once set. After setting and sealing you can the lift the foam-covered

blocks and any puckering of the DPC can be shrunk using a hot air gun, I went

with a second covering of DPC and shrunk it over the first with the hot air gun

and the blocks still fit back in the hull, that up to you. The older hulls do let water through only by a very small

amount, but over time/years it’s a problem, once you have finished the stringer

work clean back the hull of all old coatings and tank it all in epoxy resin 2 coats the second before the

first is fully dry. Moisture will always be in the hull just by temp changes its

just keeping as low as you can. Thanks for saving an old SN and keep the pictures coming good

luck. roger. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: samudj01

Date Posted: November-26-2022 at 9:43am

|

Enjoying this thread. Keep up the good work! Think about using thickened epoxy to bed the stringers instead of 3M caulk. ------------- 78 Ski Tique, 72 Skier w/302's, 93 SN w/351 & 17 GS22 w/zr409 Previous - 99 Sport Nautique w/GT40 and 87 Martinique w/351 |

Posted By: blammie

Date Posted: November-27-2022 at 3:17pm

|

You posts are well timed for me. I'm hoping you'll post more pictures. I'm just starting on my '68 Barracuda. I'll be interested to see your progress as you lay stringers back in. This is the part of the job that has me most worried. |

Posted By: andrewmarani

Date Posted: November-30-2022 at 12:42pm

|

Got the last bit of main stringers out with a router and a half inch bit, used a guide to keep the bit in the middle of the stringer and cut down ALMOST to the hull (was very careful about that!). Then I was able to split one size of the stringer off in small pieces and pop the other side out in large lengths, so not as difficult or time consuming as I expected. Pulled the windshield and knocked it down into it's component parts, will be sending the aluminum out to a local powder coat company for a new black finish. Trying to decide between a satin, semi or gloss sheen, any thoughts? I'm now into the apparently never ending grinding stage to prep the hull for fiberglass. I will post a picture once it looks like something has actually changed. Got pricing on Coosa board from a local supplier for the stringers. After laying things out, I will need 2 sheets of 1/4" for the secondaries and 2 sheets of 1/2" for the primaries in order to laminate up (3 layers wide) to get the lengths and widths I need. OMG that stuff is expensive. Still planning to go that way, just had to take a deep breath and adjust to the cost before I actually order it after getting the quote. The honeycomb board for the flooring is not available locally but some research on line says that the 26 lb Coosa board would work well for the floor but the 20 lb is too flexible. I will be going over 2 lb foam and am now planning to use 1/2" 26 lb Coosa. Anyone have a thickness recommendation? Only want to buy this stuff once! ------------- Builder |

Posted By: GottaSki

Date Posted: November-30-2022 at 3:43pm

|

For the floor you could consider using the lighter density 3/4 coosa as a core and just epoxy some mat to both sides. it gets very rigid once the glass is there on the outside to take the brunt of the compressive and tensile forces. and still wouldn't foam-fill it. neither my supreme nor response are foam filled, and they are the quietest boats in the local fleet of my hommes

------------- "There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing." River Rat to Mole |

Posted By: NCH20SKIER

Date Posted: December-01-2022 at 1:28pm

|

I had my windshield powered coated and am very pleased - for me satin was the choice. Be prepared for some sanding and finessing the parts and pieces back together following coating and the oven bake. ------------- '05 206 Limited '88 BFN |

Posted By: andrewmarani

Date Posted: December-04-2022 at 11:32am

|

Thanks, gloss had me worried, shows all the flaws. I will probably go with satin. Thoughts on how much of the gray and white pebble finish should I remove in the bilge? I need a solid bit for the stringer glass and i'm planning to coat the bilge with a white epoxy bilge coating when I finally get that far. The old pebble finish is stuck on hard, must be some type of epoxy. i'm leaning toward heavier removal close to the stringers and leaving more further inside the bilge but making sure all of it has it's surface sanded/ground to get a good bite for the new coatings. Along the lines of what shows in the picture, still have work to do around the rudder post and the bolts.. Thanks.  ------------- Builder |

Posted By: andrewmarani

Date Posted: December-04-2022 at 4:10pm

|

It would simplify the grinding and glassing at the transom if I can get the two exhaust nipples out. I'm sure others have removed them. Can I just pull the screws and tap them out with a hammer and a block of wood or does it get complicated? Thanks Andrew ------------- Builder |

Posted By: Gary S

Date Posted: December-04-2022 at 7:05pm

Should just tap out- don't hurry. Little heat from a heat gun will help too. You might have to replace those wood blocks anyway including the lift ring block and the rudder block,they use the same pre rotted wood that were deemed not good enough for stringers  As to white bilge paint think about that. I just painted one with Interlux white,it shows everything. My cooling system U dripped,it left a rust that really stood out. Personally IMHO a off white or a grey like the newer boats might be best. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: andrewmarani

Date Posted: December-12-2022 at 7:48pm

|

Removed the screws from the exhaust nipples and tried to tap them out with a hammer and block of wood but nothing moved. I will try a heat gun next and see how things go. Probably have another go at removing the pylon at the same time, working around it is a pain. Grinding is mostly done but I’m sure there will be some touch up work once I get to installing the stringers and start concentrating on exactly how the fiberglass matts are going to lay. I’m working up the layup schedule now using info from other stringer rebuilds. Once I’ve got the schedule finalized, I will post it for comments. Coosa Board has been delivered and I’ve set up an efficient cutting plan, won’t be much left after I’ve installed the stringers and deck. The secondary stringers where ¾” x 12’ and the mains where 1½” x 13’ so I’m going to lay up the secondaries out of three pieces of ¼” Coosa and the mains out of three pieces of ½”. Per some information from online, I will use a slightly thickened paste of resin to glue the Coosa together. I’m going to use a vacuum bag technique to press the three layers of Coosa together for the stringers when I glue them up. I have a vacuum pump that I picked up somewhere along the line so the rest of the vacuum bag setup only cost about $50 in fittings. Sometimes we use HEPA negative air machines on our jobs, which require venting to outside the construction area so I have 6 mill plastic disposable ducting that comes flat in a 100’ roll. Seems perfect for a vacuum bag to slide the stringers into. Just cut the length I need, install the little hose fitting, slide the stringer in, seal the ends, suck out the air and squish. What could possibly go wrong! ------------- Builder |

Posted By: andrewmarani

Date Posted: December-24-2022 at 12:52pm

|

Hull grinding is (hopefully) done. Currently I'm gluing up the stringers using the vacuum method I described earlier. Had some learning curve on that but it's working nicely, really does squish the three layers together well. Very easy to line things up once the stringer is in the bag before turning on the vacuum pump. Both secondary stringers are glued up and once my daughter wakes up, we will glue up the first of the primary stringers.. I'm coating one side of the Coosa with a flat spreader, basically just wetting in the Coosa. Epoxy on the mating piece of Coosa gets spread with a fine notched trowel. Epoxy is squeezing out of all joints so i'm getting a good coat but only a small amount comes out so sanding off the excess only takes 10 minutes or so. Once the picture gremlin is slain, I will post some pictures showing the operation. It's 15 degrees outside so if I feel really motivated in a bit I will heat up the pylon and see if I can twist it off the very cold steel base. Ahh, daughter just walked in and delegated this glue up to her brother. He objected by explaining she had already developed the necessary skills but she demanded he expand his horizons to help him with future work. Guess I am teaching her some people management techniques after all. ------------- Builder |

Posted By: 1980SN2001

Date Posted: January-12-2023 at 3:36pm

I am as new to boat repair as it gets but I recently ground down my bilge all the way to raw fiberglass on my 1980 SN to put on new Total Boat Bilge Epoxy. I tried and tried and tried to just get the spots that were lifting up and cracking but the more I ground the more I found so eventually just took it all down to raw fiberglass. I figured if I am this far and I really don't want to have to do this again if the new Bilge Epoxy starts to lift up because of the old gel coat was cracking and peeling. Also if you only do some it will definitely be very visible, atleast with the Total Boat Bilge epoxy because it shows every minor blemish underneath. This part of my repairs generated the most dust though.  Just thought I'd throw that out there. Just thought I'd throw that out there.P.S. Thank you for posting your stringer job here. I've only had my boat for about 6 months and have done a ton of work to it but I will inevitablly have to tackle the stringer job someday and these threads are a great resource. I haven't posted much at all but but this site and its users have already been invaluable to me with the knowledge and advice they freely share.  ------------- 1980 SN Project |

Posted By: andrewmarani

Date Posted: January-14-2023 at 8:44am

|

Welcome to the site. I usually start here when I plan a new repair to my boat. Thanks for the advice, I was planning to use the total boat bilge epoxy. Sounds like I'm not done grinding yet! If you haven't run across it, electrical wire size is usually a problem in the older boats, Correct Craft was a bit light with the gauge. I've run larger positive and negative wires from the dash to the engine (Negative) and solenoid (positive) and completely rewired the dash. There's a post here somewhere describing the work. ------------- Builder |

Posted By: va-river-tique

Date Posted: January-16-2023 at 7:03pm

|

Did you ever get the dimensions you needed? I think all 86 Skis have the same measurements but I do have a Silver that I can grab some numbers for you. I'm also looking to so stringers in the next year or three so this thread caught my eye along with the elephant. pylon to base of observer's seat. pylon to inside edge of battery box. pylon to base of driver's seat. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2687" rel="nofollow - Tique http://www.correctcraftfan.com/diaries/details.asp?ID=9750" rel="nofollow - Silver |

Posted By: andrewmarani

Date Posted: January-18-2023 at 5:01pm

|

No, I still need those dimensions. If you can send them that would be awesome. Yeah, i've been following the elephant discussion as well. Not sure what I can do to help. Currently I have the main stringers made, cut to the curve of the hull and notched for the engine cradle etc. Too cold last weekend to epoxy them in place and I'm taking my wife away this weekend just for fun or, perhaps, to make up for all the previous weekends spent working on the boat... Since it's been too cold to epoxy, I've started roughing out the Coosa floor panels and the installed secondary stringers give me a level line at the right height to work from. Lot's of measuring, cutting and shaving to fit the curve of the boat's sides. Once I have the floor panels cut and dropped temporarily in place, those dimensions will help me figure out where to reinforce for screws. i've got pictures of the progress to post but waiting for picture posting to go active again. ------------- Builder |

Posted By: va-river-tique

Date Posted: January-30-2023 at 3:13pm

|

I took these measurements from the bow side of the pylon. pylon to base of observer's seat is 12 1/4 inches. pylon to inside edge of battery box is 26 1/4 inches. pylon to base of driver's seat is 6 inches. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2687" rel="nofollow - Tique http://www.correctcraftfan.com/diaries/details.asp?ID=9750" rel="nofollow - Silver |

Posted By: andrewmarani

Date Posted: January-30-2023 at 3:44pm

|

I have all the stringers epoxied down but not yet glassed in. I'm now laying out and cutting the deck Coosa to fit but not install. Once I have the deck fitted, I will use the scraps to finish off the little parts that epoxy to the secondary stringers at the exhaust mufflers and the sections next to the motor and the primary stringers. THEN i can finally glass in the stringers and move on to foam. I will post my Coosa cutting plan at some point, though I keep revising it as I see a slightly better layout. This has been a very patient process. I'm working outside so I'm temperature dependent on any epoxy work. I put a skirt (using something called a concrete blanket that we use in my company) around the hull to the ground. Two electric heaters under the boat on a 45 degree day will raise the hull to 60 degrees, good enough for West Systems fast set epoxy. But I need 45 degrees on a weekend to actually do any epoxy work. Anyway, your dimensions are very timely and appreciated. Once I have the deck fitted, I'm going to set the seats and engine cover and mark out where everything is fastened onto the deck parts in permanent marker so I can install the anchor points in the Coosa. Should be there by this weekend with a couple of work nights this week. ------------- Builder |

Posted By: andrewmarani

Date Posted: January-30-2023 at 4:03pm

|

Adding in a lessons learned... I am using West Systems fast set epoxy (bought the 4 gallon jug at West Marine) and Total Boat for the fiberglass matts. I also bought six tubes of Total Boat Thixo adhesive epoxy to glue the stringers down. I really liked the Total Boat adhesive epoxy constancy and the using a caulk gun makes it super simple to install, plus you can stop in the middle of tube come back a day or week later and start up again just by changing the nozzle. BUT, due to the internal stuff in the tube, you probably get a half a tube of epoxy from each tube so it takes a lot of tubes and the stuff is moderately expensive. I used four tubes to install and fillet one secondary stringer. Since I was reluctant to give up the simplicity of using a caulk gun but didn't want to spend that much money, I took an empty tube apart and redid the plunger part to make it shorter and removable. Now I mix up the West System to a peanut butter consistency and pour/scoop it into the tube, add the plunger and put it in my caulk gun. Works great and i've used that same tube for the rest of the stringers and the fillets. Pumping epoxy out of a tube is way cleaner and faster then scooping it out of a mixing bucket and apply it with a spatula. Does take 15 minutes or so to clean up the tube with acetone so it will work next time out. ------------- Builder |

Posted By: andrewmarani

Date Posted: January-30-2023 at 4:12pm

|

One more, then I need to go back to money making work. Leaving that 1" of old fiberglass on one side of the primary and one side of the secondary stringers (shows in my pictures) was awkward during demolition but made reinstalling the stringers very easy. Just put the epoxy on that 1" of fiberglass, put more on the bottom and push the stringer down and over against the 1" fiberglass. Then wedge a couple of boards from the sides of the boat to the secondary stringer to keep it pinned in place. On the primary, just wedge boards from the secondary. No need to worry about getting the stringers in the right spot or keeping them straight.

------------- Builder |

Posted By: Gary S

Date Posted: January-30-2023 at 7:07pm

|

If you want to save some money over the West system and have quality products check this place out- http://www.uscomposites.com/products.html" rel="nofollow - http://www.uscomposites.com/products.html many boats here in past have used their products. They ship fast and are there to answer any questions. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: andrewmarani

Date Posted: February-04-2023 at 4:42pm

|

Going to back up and post some pictures showing the progress now that I understand the IMGBB picture posting thing. Starting with the hull cleaned out, ground down and ready for stringers. Probably still have a bit more work on the bilge section. https://ibb.co/b2FR3W6" rel="nofollow">  https://ibb.co/2s2yphL" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: February-04-2023 at 4:50pm

|

Stringer pieces cut and ready to epoxy up. Vacuum bagging a secondary stringer. https://ibb.co/GRHsL1C" rel="nofollow">  https://ibb.co/sFGVy13" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: February-04-2023 at 4:55pm

|

A secondary stringer fresh from the vacuum bag. Both primary stringers glued up, notched, cut to the hull shape and ready for installation. https://ibb.co/VJtPwKL" rel="nofollow">  https://ibb.co/gRvRhYR" rel="nofollow">  EDIT: Pretty as those stringers are, I made a mistake in the notches for the engine mount bolts. See my edit note on page 3 where I posted the layout sketch for the stringers.

------------- Builder |

Posted By: andrewmarani

Date Posted: February-04-2023 at 5:11pm

|

Secondary stringers being epoxied into place. https://ibb.co/vZZbMzJ" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: February-04-2023 at 5:20pm

|

The current state of affairs. Primary and secondary stringers epoxied into place but not glassed in. That section of deck is only installed temporarily, as is the engine frame. Working on fitting the decking to the hull and laying out the seats and engine cover attachment points so I can reinforce those locations. I need the scraps left from fitting the deck to make up the stringer build outs at the engine and the exhausts. Tomorrows project is to start cutting up those scraps to into the stringers. https://ibb.co/8cW7fmZ" rel="nofollow">  https://ibb.co/3SzVT8f" rel="nofollow">  ------------- Builder |

Posted By: fanofccfan

Date Posted: February-04-2023 at 10:06pm

|

Nice progress. Oh how the pictures help entertain me and others! ------------- 2004 196 LE Ski 1969 Marauder 19 1978 Ski |

Posted By: samudj01

Date Posted: February-05-2023 at 9:31am

|

Looking good. Thanks for the pics ------------- 78 Ski Tique, 72 Skier w/302's, 93 SN w/351 & 17 GS22 w/zr409 Previous - 99 Sport Nautique w/GT40 and 87 Martinique w/351 |

Posted By: andrewmarani

Date Posted: February-05-2023 at 9:42am

|

At first I leveled the boat using a 4’ level but I wanted the boat exactly level with no twist when I started epoxying in the stringers.. While trying to figure out a simple way to check for twist in the hull and level the stringers as I cut them to the shape of the hull, I remembered my laser level. The laser has a magnet hanger so I used some small hose clamps to attach a long steel bolt to the back davit hanger, you can see the level and the bolt in the picture. I set the laser at 8” above the old floor level and rechecked the boat for level. No surprise, it wasn’t exactly level and had a slight twist. By the way, what points to measure for leveling front to back is a bit of a guess as the original floor definitely wasn’t flat. I used the 4’ level and a long straight edge to check the sides, from side to side and the laser level to compare points on either side of the bottom working from back to front. The boat is hung from the davit points but I’ve got supports under the back corners and the front roughly at the windshield to take some load off the davits points and stop the boat from rocking when I’m in it working. I adjusted the davit hangers and shimmed the supports until I had the boat hull level by laser. No matter how much I tried, if the hull was level side to side, the top of the sides, side to side just behind the windshield was a ¼” out by the 4’ level. Back of the boat side to side at the top of the sides was level. So the boat was built with a slight twist, not enough to matter and I elected to level the floor to the hull, not the sides. Once the stingers where epoxied in I checked them with the laser. Three where good at 8 ½” below the laser. One secondary was correct in the back but was a ½” high by the time it got to the front. 15 minutes with a belt sander leveled it out to match the others. https://ibb.co/DYqkrJF" rel="nofollow"> ------------- Builder |

Posted By: wayoutthere

Date Posted: February-07-2023 at 5:26am

Nice work, great idea using coosa |

Posted By: blammie

Date Posted: March-02-2023 at 4:48am

|

So I'm also in the process of rebuilding a '68 Barracuda. I have one stringer removed and ran into a snag sourcing new stringer material. I originally was thinking I would use a vertical grain Douglas fir, until I was quoted over $900 a piece for a 2x10x14. I can get by with a 2x8 and shave a little off the price, but probably not enough to make sense. Pretty much, it seems I am priced out of anything with vertical grain. I'm now leaning towards Coosa board, having found a source in the Detroit area, and realizing it is going to be cheaper or comparable to Spruce or DF. One concern I have is the motor mounts. I've read some guys mentioning difficulty keeping screws set in Coosa. Is there any truth here? I'm looking for guidance from guys that have actually been through the process. I was initially thinking two layers of 3/4" with staggered seams for the stringers, but I'm thinking I might mimic Andrew and go with 3 layers of 1/2". It feels like those joints will be stronger. My question is, how do I assemble them? I don't have a vacuum setup, but I do have plenty of clamps. Obviously, I'll resin them together, but should I just clamp, or should I consider screwing them also? and if I screw them, what do you suggest, wood screws, or possibly through bolts? Also I'm wondering about my motor mounts. Should I expect any issues. I am figuring to pre-drill the stringer and secure the mounts with lags, just like I would with wood. Your advice would be much appreciated. The further away I get from wood products, the further I am from my wheelhouse. |

Posted By: andrewmarani

Date Posted: March-03-2023 at 4:32pm

|

If I hadn't used the vacuum set up, I would have used a combination of stainless deck screws and clamps. I was originally worried about not having enough time to epoxy all three layers in one move but my basement was about 60 degrees and I had lots of time once the material was spread thin on the Coosa to adjust the pieces and set up the vacuum rig. So I figure you should have plenty of time to lay up three pieces and run screws into them. Make sure you put epoxy on both mating surfaces. I wet one out with a smooth spreader and then spread epoxy on the other with a fine notched spreader. I put silica adhesive filler in the epoxy to thicken it some. I've run screws into the Coosa and they take up fine but are easy to over torque and strip out. I would glue up all three layers, then clamp a section tight, run some screws into that section to hold it tight, then move the clamps to the next section and repeat. An alternate would be to set the three layers on a long 2x8 and screw right through the Coosa into the 2x8, once it's set up, pull the screws and your good to go. On the 86', the engine mounts bolt to the aluminum frame that sits on the stringers so no worries about them tearing out. I am NOT planning to run lags down through the frame into the Coosa (like it was originally), instead I plan to through bolt the frame to the stringers from the side. I would not trust heavy uplift loads to a wood type screw in the Coosa. If you don't have the aluminum frame to support the engine mounts, I would cut some holes or a slot down near the bottom of the stringer, put a block of aluminum in there as a load spreader and through bolt down from the engine mount, thorough the stringer, through aluminum block and put a nut and lock washer on it from underneath.

------------- Builder |

Posted By: andrewmarani

Date Posted: May-08-2023 at 7:48pm

|

Been a while since I posted on this, life sometimes gets in the way of the best of plans. I glassed in the secondary stringers a month ago or so. I cut and fitted most of the 1/2" coosa for the floor. This weekend I epoxied in the short pieces of stringer that sit next to the mufflers. The coosa is only a 1/2" thick and that didn't seem wide enough for a location that supports both a fixed section of floor and the removable panel next to it so I epoxied another piece of 1/2" about 1 1/2" tall against the short stringer piece to widen it to 1", You can see the clamps holding the second piece in place in a picture. You can't see it in the picture but I cut a 45 on the down edge of that added piece so the glass will wrap down it easily. https://ibb.co/BTqMWJP" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: May-08-2023 at 8:00pm

|

Coosa is not a great screw holding material so I'm using T nuts to hold down the drivers seat, the observers seat, the hinges for the engine cover and the hinges for the back seat. You can see the layout of the seats on the upper side of the front section of flooring and you can see the T nuts and the doubled up coosa on the underside. I've also applied a layer of glass to the underside as reinforcing. I still need to cut out the hole for the battery box. Many thanks to va-river-tique for those dimensions, major help. https://ibb.co/rHCmmWL" rel="nofollow">  I seemed to be pulling the observers seat support out on a regular basis to crawl up under the front for one reason or another. In the earlier floor I installed two machine thread inserts into the plywood floor and used two 3/8" bolts inside the base (with an added wire grab kind of thing that allowed me to remove them by hand) to secure the base to the floor. Same sort of operation now with the Coosa, only i've got T nuts in the Coosa to run the bolts into. https://ibb.co/nmXf3bF" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: May-08-2023 at 8:16pm

|

So take a closer look at the upper side of the floor where the drivers seat base is drawn in. See that short diagonal line on the corner that will be next to the side of the boat? DO NOT run a screw through the drivers seat base in that location! Why, you ask? Well, the hull of the boat is right there on the other side of the floor and people have been know to screw through to the outside of the boat, causing a leak that puzzled them for months until they cut their hand feeling along the bottom of the boat looking for cracks. That's also why the reinforcing on the underside of the floor is clipped off in that area. Moving on. Does anyone know where to buy a new battery box? Mine is in reasonable shape except for the top flange, which is wavy as hell. It's going to be very hard getting that thing to sit flat on the floor and take carpet neatly. Rather buy a new one if I can. https://ibb.co/pZGh1Ky" rel="nofollow">  ------------- Builder |

Posted By: andrewmarani

Date Posted: May-08-2023 at 8:24pm

|

Last picture for now, showing the front floor sitting in place for fitting check. You can't really see it in the earlier stringer picture but i've notched the stringers down at each floor joint location so I can run a piece of 3" wide Coosa under the seam between two pieces of flooring to tie the two pieces together when I epoxy them down. https://ibb.co/HryYtsG" rel="nofollow">  ------------- Builder |

Posted By: Jonny Quest

Date Posted: May-08-2023 at 10:51pm

Looking good Andrew! ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: andrewmarani

Date Posted: September-19-2023 at 4:57pm

|

Didn't really realize how long it's been since I posted on this. Life's been doing it's thing: went on vacation out of the country, twice. Had a neck operation, all good, plus I'm 3/16" taller now. I have managed to keep going on the boat, closing in on the need to foam the interior. Posting a series of pictures of the progress. This shows the rolls of fiberglass ready for the stringers, folded in half to create a crease to make it easier to fit, four for each side. 4" wide first (2" on floor, 2" on stringer) then 6" wide, then 8". The wides rolls are the pieces that fold down over the top, 8" again but only needed four.  ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 5:05pm

The top of the main stringer has lots of dips in it. this shows the cuts in the glass to get it to lay into the ups and downs. Mostly worked, i'm sure an expert fiberglass dude has some better way of doing this! ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 5:06pm

Right main stringer glassed in. you can see all the elevation changes in the left stringer. ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 5:46pm

Next up, you can see the ledger I glued to the sides of the boat to catch the edges of the floor. Had plenty of thin Coosa scraps to make up the ledgers. Used some thin flexible wood to hold the ledger in place while the epoxy tightened up. To locate the ledger I used a laser level to draw a black marker line around the hull a 1/2" below where the top of the floor will be and checked to make sure that matched the top of the new stringers. ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 5:51pm

The Coosa floor is mostly cut and fitted. I still have to make the bow piece and do some fitting around the engine hole. This shows the cut out for the battery box. To get the box edges to sit flush with the floor I dished out the Coosa using a Mikita belt sander that takes a 1" belt. Wish I had bought that machine earlier, makes controlled removal and cleanup of fiberglass easy. ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 6:00pm

|

This shows the little supports for that lowered section of floor on either side of the engine. I'm not tabbing them in, just laying down a nice fillet on all sides. The narrow pieces laying on the stringers go on top of the supports. The Coosa leaning against the hull are the pieces of floor next to the engine, fitted to the hull but still need to adjust for the engine hole. I'm mostly only able to put in an hour here and there right now so time is a factor. I bought more of the Totalboat Thixo, this time in the double tube, which gives a lot more epoxy for the price. Still expensive at $45 a double tube but I had the special gun already and now I can just put a new nozzle on the tube and epoxy without having to spend time mixing stuff and then clean up.  ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 6:07pm

And this is where i'm at as of Sunday. The little narrow strips are installed and filleted into place. Next is trimming the floor to the engine hole. Then spending some time laying out and making the vertical closers that sit on the pieces I just installed and rise to the underside of the coosa floor. The flooring in the picture is just sitting there loose.  ------------- Builder |

Posted By: andrewmarani

Date Posted: September-19-2023 at 7:04pm

Since i'm closing in on foaming the floor I am also now in need of the hose that gets buried in foam under the front floor. Never liked the cheap plastic stuff installed originally in the boat. Spent some time on the site looking for an answer and McMaster Carr turned up a couple of times but didn't like what I found and it was expensive. Finally turned up the stuff below at Fisheries Supply. https://www.fisheriessupply.com/trident-marine-trident-polyduct-hvac-duct/481-3000" rel="nofollow - https://www.fisheriessupply.com/trident-marine-trident-polyduct-hvac-duct/481-3000 Still expensive at $6.83 a foot but looks nice and is very flexible. 3" Trident Marine Polyduct HVAC Duct. ------------- Builder |

Posted By: andrewmarani

Date Posted: September-21-2023 at 3:21pm

|

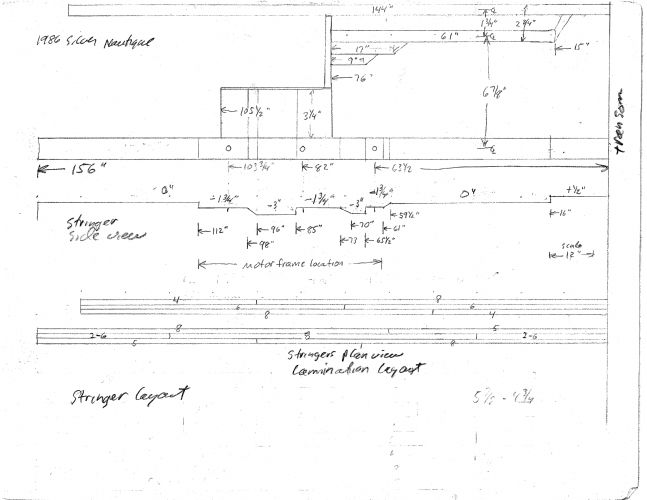

This is the stringer layout for my boat. The old stringers where likely cut from a standard pattern but I’m not sure how tight they followed the pattern. I expect each boat varies a little based on what I’ve seen on this boat. Best if you use your stringers to layout your new stringers. But if you can’t use your stringers, this should get you pretty close for boats like mine. Top of the page is a plan view (looking down) of the secondary stringer, the space for the exhaust hose and the top of the main stringer. The circles are bolt holes in the aluminum engine frame. Below that is a side view of the stringer showing the dips, their locations and depths. The gas tank is shown at + ½” because the floor is a ½” thick and the two aluminum angles under the tank sit basically flush with the top of the floor, making the bottom of the gas tank maybe a ¼” above the floor. 0” elevation is the underside of the floor. Everything is measured from the transom of the boat in line with the thing you are laying out, keeping in mind that the main stringer hits the transom is a bit further aft than the secondary stringer because of the curve in the transom. At the bottom of the page is a plan view of the secondary and main stringers showing the lamination schedule. As you will see in a following post, the secondary stringer is made up of ¼” Coosa laminated together to get to ¾” thickness and the main stringer is made up of ½” Coosa to get to 1 ½” thickness.

EDIT: In the above sketches I put the notches in the stringers to match the original, including the locations of the notches for the engine mount bolts (deepest notches on the sketch). This was a mistake, the front engine mount bolt notches are much longer than needed and the back notches too tight. I have way too much space on the front notches and I had to sand out and then re-glass the front part of the back notches to get a bit more clearance for those bolts. In addition, the front of all the notches are sloped, for no reason I can discern. Better plan is to make the notches run about 1 ½” past the bolt locations in the engine frame and make the ends of the notches vertical with rounded corners at the bottom and top of the vertical cuts. ------------- Builder |

Posted By: andrewmarani

Date Posted: September-21-2023 at 3:34pm

|

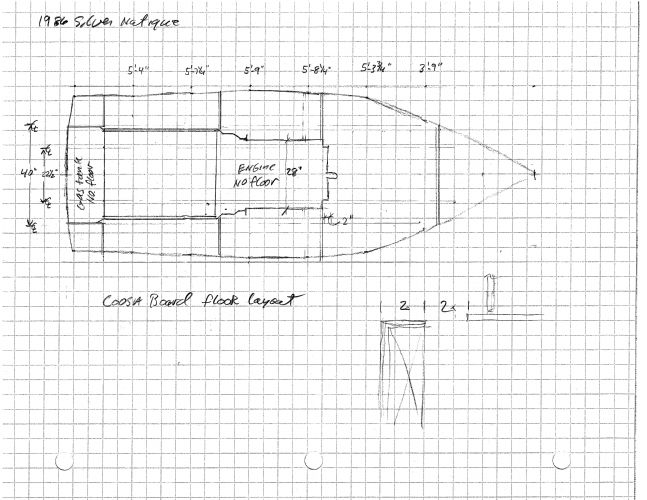

This is the floor layout plan using 4x8 sheets of Coosa or any 4x8 sheet material. You can ignore the numbers at the top of the page, that’s just me trying to see how the side of the boat curves. I templated the curve using a piece of heavy cardboard set to a line running down the center of the boat, marking, trimming with scissors, remarking and trimming till it fit neatly to the curve while the other edge of the cardboard stayed parallel to the boat center line. The faint lines running parallel to the boat are the stringers. Next post will show the cut schedule for the 4x8 sheets.

------------- Builder |

Posted By: andrewmarani

Date Posted: September-21-2023 at 4:26pm

|

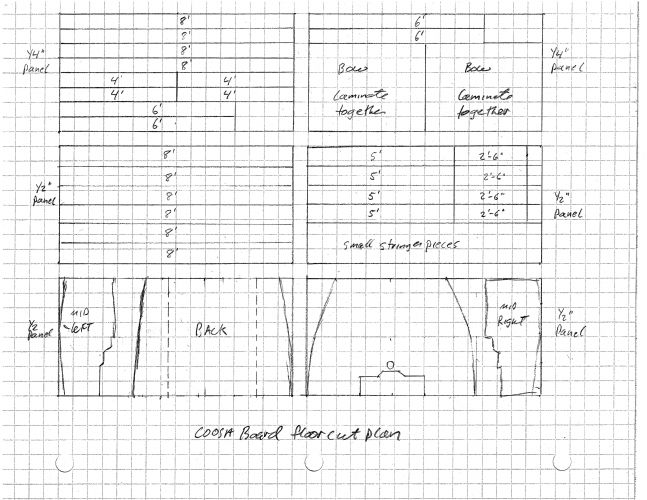

This is the Coosa Board cut plan. Per this plan you need two ¼” x 4x8 sheets and four ½” x 4x8 sheets. All the long skinny pieces are for the stringers. The stringer pieces on the ¼” board are for the secondary stringers and they are 6” wide x 8’ or 6’ or 4’. The stringer pieces on the ½” boards are the main stringers and they are 8” wide x 8’ or 5’ or 2’-6”. The rest is pretty obvious, the only funky thing is I made the floor piece up under the bow by laminating two ¼” pieces together, otherwise you would need to buy another sheet to finish up. If you are careful in your layout and cutting there will be plenty of small scraps left to make up the extra pieces next to the exhaust hoses, the little shelf on either side of the engine and the various other odds and ends, like the two roughly 11” x 14” pieces on either side of the gas tank. Dotted lines on the one piece are the cut out for the removable panel behind the engine. I would wait to cut that out till the final fitting of the floor pieces after everything under the floor is installed. Side note: since the Coosa board is only a 1/2" thick, I added a 1" tall x 1/2" thick piece of scrap to the Coosa board that makes up the non-stringer side of the exhaust hose space. I put it on the outboard side, the side closer to the secondary stringer. So the top of that piece is now 1" wide to give more landing space for the removable panel. You can see it in one of my other pictures.

------------- Builder |

Posted By: andrewmarani

Date Posted: October-03-2023 at 9:34am

|

Getting close to foam time so I've been reviewing posts on foaming the hull. I could start foaming from secondary stringer to the side of the boat now in most of the boat. I will be using 2 lbs foam from US Composites. The idea of drilling holes in the Coosa floor and pouring in foam makes me nervous because I cannot tell if i've foamed the entire cavity. Plus I'm putting a bunch of holes in the new Coosa floor that I have to patch. However, it does seem the easiest solution. One way to insure a full cavity would be to fill cavities before the floor goes down and then shave the foam flush with the top of the stringers. I would then use a large notch troll to spread thickened epoxy on the foam and set the floor on top with some sand bags to weight it down and let the epoxy set up. I expect it would be hard to shave down the foam flat and it would take a lot of epoxy to bond the floor to the foam. Another way would go insure a full cavity is to pour the foam into the cavity, stretch some plastic tight over the stringers and set the floor panel on top with some weight on the floor panel. Let the foam expand to the underside of the floor panel/plastic and harden. Take up the floor and peel off the plastic. If I do it neatly I should have a smooth flat foam finish, then epoxy the floor down as as noted above. Has anyone done anything other than the holes through the floor method? Any thoughts on the other two methods I've outlined above? Can someone who's foamed a 1986 Nautique or similar boat give me an idea of the quantity they used? I will calculate it out but that's going to be a rough number considering the curving shape and differing depths involved. Thanks ------------- Builder |

Posted By: TRBenj

Date Posted: October-03-2023 at 9:44am

| Why put a Coosa floor over foam cavities? Seems a waste. Just glass over the foam like the factory did. Save the coosa for the spans over the bilge. |

Posted By: andrewmarani

Date Posted: October-03-2023 at 9:59am

|

Well, i'm long past that point. Coosa floor is basically cut and fitted for the entire boat. Plus my abilities to fiberglass in a flat floor over the foam are probably not up to that level of finish, not without a lot of fairing compound and sanding. ------------- Builder |

Posted By: uk1979

Date Posted: October-03-2023 at 12:32pm

|

Did something similar but wrapped the foam in DPC plastic sheeting, left plenty above, just lift out the foam section.. fold over and get the DPC firm as you can with tape, then go over it with a heat gun to shrink it tight. I put a plastic packer on top before foaming to give room to fold over, I think its not needed if you heat gun it, I used pallet stretch wrap over my blanking boards with holes in. Have fun and do what work for you ..   ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: uk1979

Date Posted: October-03-2023 at 12:37pm

More pictures I'm a bit rusty on posting..  ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: andrewmarani

Date Posted: October-03-2023 at 1:00pm

|

so, smooth ply with plastic wrap on them and holes in the ply to pour the foam through. I see the weights and clamps to hold the boards down as the foam expands. I see the yellow foam at the holes and where it puffed out around the edges. Is the white material a flooring that you held down with the plywood? Like the giant air ducts! ------------- Builder |

Posted By: uk1979

Date Posted: October-03-2023 at 1:48pm

|

I used 18mm Mdf cover boards as I have lots of it .. the white plastic is correx I stuck to the under side of cover boards as a spacer to give room when removed to fold the DPC over the top of the foam to enclose it … as I said if you use.a heat gun it’s not needed . ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: andrewmarani

Date Posted: October-03-2023 at 4:26pm

|

Are you putting down plywood flooring or are you building up the floor by putting multiple layers of fiberglass cloth right on the foam or I guess on the DPC? If plywood, are you glueing or somehow sticking the plywood to the DPC? ------------- Builder |

Posted By: uk1979

Date Posted: October-03-2023 at 5:58pm

|

This was all along time ago and coosa was not available in the uk ..so used 8x4x1/4 fibreglass sheet cut and epoxied down, Things are much better now with all the wind turbines built here now much more available to play with. Good luck with the build keep the updates coming Roger. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: 1980SN2001

Date Posted: October-13-2023 at 5:15pm

|

Very nice work. Great attention to detail. Thank you for sharing the process! ------------- 1980 SN Project |

Posted By: andrewmarani

Date Posted: December-16-2023 at 3:57pm

|

Project slowed down a lot while I got a partial knee replacement but still managed to move some stuff forward. At this point, I'm ready to install the smaller sections of flooring, the pieces just to either side of the motor. Figured I should start small. tomorrow I will epoxy them down to the stringers and sides of the hull. I plan to foam under them before moving on so I can see how the foaming works. I used scrap 1/4" Coosa at the floor joint locations to reinforce the seam between two pieces of Coosa. You can see them in the two photos.   ------------- Builder |

Posted By: andrewmarani

Date Posted: December-16-2023 at 4:04pm

|

I wanted something to move out any moisture that made it's way into the foamed areas. I'm using a piece of cotton rope, basically clothes line that you can buy at a hardware store to wick any moisture out to the holes I left in the stringers. From there it can drip into the bilge. To hold the rope in place when I pour in the foam, I put dabs of thickened epoxy where the rope is and pushed the rope into it. 2/18/24 edit, this was a fail. The dabs of epoxy soak in and seal the cotton. The foam fill seems to do the same thing. I had some water laying against the rope after a rain and it did NOT soak downhill and drip into the lower stringer area. I'm ignoring this issue and moving on! When I installed the secondary stringers, I fitted some thin wall plastic pipe through them to leave drainage holes. This was a big pain to make, fit and glass over. On the primary stringers I just cut a 1" hole in the stringer, glassed over it and cut it out with a dremel afterwards, much easier, faster and did a better job. I ended up chopping up the plastic pipe when I put the wicking rope in.  ------------- Builder |

Posted By: andrewmarani

Date Posted: December-16-2023 at 4:19pm

|

Water lays under the battery box and in front of the pylon. It's blocked by a hump in the hull at the pylon. Always bugged me. In this picture you can see i've filled that area in with epoxy mixed with a fairing compound so that any water that does make it up there will run back to the drain hole. The boat is currently level, so I filled the area in front of the pylon with water till it started running over the hump at the pylon. I marked the outside edges of the puddle, dried the area and then filled with to that line with epoxy. I put the epoxy in roughly a 1/4" thick at a time. I checked ahead of time to make sure this infill didn't interfere with the underside of the battery box, turns out there was plenty of space. Got some leaves laying in there in the picture but it actually has a pretty smooth finish. Trick is to mix the epoxy slowly, minimizing bubbles. You will still get some but waving a propane torch, very quickly, over the wet epoxy pops them. Have to do that multiple times as the epoxy sets because they drift up to the top pretty slowly.  ------------- Builder |

Posted By: andrewmarani

Date Posted: February-22-2024 at 1:50pm

|

My knee rebuild has been a huge success. I’ve been fully back up to speed for 2 months. With all the knee exercises, I’m better than before, no aching knees at the end of the day. So work on the boat has accelerated significantly and I expect to be done for summer skiing. Still debating with myself on slalom skiing… I had planned to use an aluminum paint on the engine frame but decided to save myself some work and dropped it off at the same powder coat company that did my windshield aluminum. I am still planning to clean and paint the gas tank. I epoxied down and then foamed the two smaller pieces of flooring on either side of the engine. Per the picture I forgot to cover one of the drain holes! Somehow, I forgot twice more, as seen in some of the following photos. Outdoor temps were in the 50s, so I heated the underside of the hull, which got the hull temp to around 65-70. I made a hot box and heated the foam resins up to 90 degrees before mixing them. That combination gave me a nice high expansion on the foam. Hot resin and good mixing for 45 to 50 seconds are an absolute must to get good expansion. I cut 2” holes in the Coosa to pour in the resin. I saved the rounds and will epoxy them back into the floor before I carpet.   ------------- Builder |

Posted By: andrewmarani

Date Posted: February-22-2024 at 4:46pm

|

Getting the battery box installed at the right elevation and location was a planning challenge but execution was easy. My solution was to recess the battery box flange into the Coosa, set that section of flooring in place loose, epoxy the battery box to the Coosa and down to the hull. That beige epoxy infill I Installed to stop trapping water under the battery box hits the depressed drain in the box, causing the back of the battery box to sit a ¼” high. Dishing out a hole in the epoxy infill with the Mikita 1” belt sander solved the issue and gave me a spot to epoxy the back of the battery box down. I used some scrap Coosa to build up from the epoxy infill and support the two front corners of the battery box. I plan to epoxy additional supports under the box to make sure nothing moves in the future. After everything set up I cut the flooring free of the battery box leaving a 2” ribbon of Coosa floor around the epoxied in place battery box. I used some ½” scrap Coosa to epoxy a lip under the Coosa flooring around the box to create support for the rest of the floor. When I install this section of Coosa floor, I will epoxy it down to those recessed scraps. Battery box epoxied to floor and to hull.  Floor cut away, leaving battery box epoxied to hull  ------------- Builder |

Posted By: andrewmarani

Date Posted: February-23-2024 at 2:31pm

|

To create the template for the bow floor, I set a thin straight piece of wood from battery box to point of the bow at the elevation of the floor then marked the side to side dimensions every 6”. I transferred that to a piece of cardboard to get close and then test fit and scribed lines on the cardboard till it fit neatly under the bow. Transferred that to the Coosa, after a bunch of test fits and some sanding I got a nice fit for the Bow floor.

------------- Builder |

Posted By: TRBenj

Date Posted: February-23-2024 at 5:22pm

| Do you have drains for foam filled cavities? Meaning bilge water has a direct path to foam? |

Posted By: andrewmarani

Date Posted: February-23-2024 at 6:35pm

|

yeah, I cut round holes in four locations in each of the stringers at the base where they hit the hull. So the main stringer has two holes that go through it from foam side to bilge side and the secondary has four that would allow water to flow down toward the primary. I planned to use the cotton rope to wick out any moisture that formed inside the foamed areas. After seeing the foam and how tight it forms up and grips the fiberglass, nothing is getting in or out of those holes. Waste of time installing them and the cotton wick. I had to use a block of wood hitting the end of a drywall spackle knife to cut that blob you see in the bilge free of the fiberglass. ------------- Builder |

Posted By: andrewmarani

Date Posted: February-23-2024 at 10:00pm

|

Need some carpet suggestions. I did some searches and turned up https://marinecarpeting.com. Anyone buy carpet from someplace they like? Looks like 20 oz is standard. Depending on cost any reason not to go to 24 oz? They also have Shaw indoor outdoor carpeting. That's a manufacturer subs i work with use on job sites. I might be able to buy that from a sub I know and get a better price. Anyone work with Shaw? Previous searches turned up DAP Weldwood All Weather Outdoor Carpet Adhesive to glue it down. anyone have pros or cons? Thanks Andrew ------------- Builder |

Posted By: TRBenj

Date Posted: February-24-2024 at 8:01am

|

Interesting. IMO, any path that allows water to drain also allows water to enter… I have thoughts on which I think is more likely! 16-20oz carpet would have been original. The thicker the carpet, the more plush it feels, and the more water it holds. |

Posted By: andrewmarani

Date Posted: February-25-2024 at 10:45am

|

Picture shows a test fit of the two front sections of floor with the driver’s seat in place and the fit around the installed battery box. I needed to check where my feet landed when sitting in the seat to make sure my size 13's missed the vent tubes and other pipes i will discuss shortly. I won't have the airbox with it's sloping footrest so I also needed to locate a footrest I will make from some old mahogany gym bleacher wood I have laying around. I will epoxy some stainless T nuts into the Coosa floor so the footrest is removable. When this thing is done, removing two bolts from the observers seat base and two bolts from the foot rest will give under the bow deck access like you see in the picture. I've spent enough time under there over the years to want easy, clear access. Even the drivers seat has T nuts and machine screws holding it down and can be pulled, though that's more complicated.  ------------- Builder |

Posted By: andrewmarani

Date Posted: March-23-2024 at 11:59am

|

Originally the wire harness, speed tubes, steering and throttle cables and the bilge pump tube all ran in one pipe from engine to the bow. I’ve broken those into individual pipe chases for ease of repairs in the future, creating the need for some creative pipe bending using heat. And lots of different holes in the bow floor and that bulkhead behind the battery box. The steering cable has a 16” stainless bar on the end so the 2” pipe has two very light bends in it so the pipe can turn up through the bow floor and still allow the bar to slide through. At this point, all the flooring is cut and fit. With all the Coosa in place, I have a nice flat floor with only the pylon interrupting it. Next step is to test fit the carpet I bought while nothing is in the way.

------------- Builder |

Posted By: andrewmarani

Date Posted: March-23-2024 at 4:50pm

|

Bought 8’-6” wide carpet and tested it in the boat today. Not ready to install, still need to finish epoxying the floor down and install the foam. I was worried the 8’-6” wide carpet wouldn’t be wide enough to run up the sides but that turned out fine. I was hoping to be able to wrap the carpet up the sides without cutting. I think that would work starting at the back and getting about halfway to the front of the boat but after that the curve and flair of the side is going to create folds, so that plan is out. I’m going to have to cut it at the floor to side transition like was done originally. I was going to trim the carpet to fit today but I think it will work better if I glue the carpet down to maybe 6” from the sides, leave the last 6” loose and then cut it at the floor to side transition. Nothing moves during or after the cutting that way.

The original carpet trim strips are definitely not made for a 90 degree turn up the sides, CC just kind of made it work. If I reuse them I think I need to actually turn the side carpet out onto the floor a half inch or so to get it under the trim strip so the carpet doesn’t ravel. The floor carpet then slips into the trim on the other side. Does anyone have a source for a carpet trim strip that’s designed for a floor to side transition? Seems like a normal detail and there should be a trim piece for the 90 degree transition.

------------- Builder |

Posted By: KENO

Date Posted: March-23-2024 at 4:57pm

On those year boats like yours, with rotary helms, you don't need to pull that 16 inch bar forward and around any corners to get the cable out. You remove it by pulling it out of the support tube at the back disconnecting the cable at the helm, taping a rope about 20 ft long or so and a plastic bag around the cable at the front end and pulling it out from the rear. Going back in, you tape the new cable end to the rope that's in the tube and pull it forward with the rope. The big awkward rear end never has to go around any sharp bends In the condition you're in right now, snake a rope through for when it's time to pull the cable through. If it was rack and pinion steering, then it's a different story

|

Posted By: TRBenj

Date Posted: March-25-2024 at 10:32am

| Not following your thoughts on the carpet trim. Walls should be cut at the floor, the trim sits up almost 1/2” and will cover that edge no problem. Floor should be cut 1/2-1” away from the wall so it tucks cleanly into the trim channel. |

Posted By: andrewmarani

Date Posted: March-25-2024 at 10:46am

|

The trim that came with the boat is a 1/2" thick, maybe a touch more and sits flat on the floor. There's no spot to tuck the side carpet into it unless I turn the side carpet out onto the floor a half inch or so. See the picture above. left side is where the floor carpet tucks into the trim. Right side goes against the side of the boat and tapers down to less than a 1/4" and is designed for carpet to tuck under it. I spent sometime on line looking at boat carpet trim and nothing is designed for a floor to side transition, don't really see boats with carpet on the sides much at all. I did find some trim that matches the old trim in the picture above, so if I need to go that route I will likely buy new stuff since it should be more flexible than the very stiff stuff I took off the boat. A picture of a relatively new Nautique showing how they currently handle that trim would be nice. Assuming CC still runs carpet up the sides of the boat. Thanks Andrew ------------- Builder |

Posted By: TRBenj

Date Posted: March-25-2024 at 9:55pm

| Nothing really tucks under from the wall carpet. Not sure why this is so confusing. It’s been several years since cc has been putting carpet in boats- not sure what you’d hope to learn. They used the trim in question at least ‘80-09, should still be available to buy from Nautique parts and others. Not exactly a mystery. |

Posted By: andrewmarani

Date Posted: March-26-2024 at 11:13am

|

It's not difficult to solve, I can definitely make it work. it's just frustrating to me that something that's actually designed for this issue isn't available, I can be a bit ocd about details. I will turn the side carpet onto the floor a half inch to get it under that lip on the right side in the picture so it doesn't ravel. The trim originally used on the boat and the one at Nautique Parts are designed for a carpet to VCT floor transition, flooring subcontractors we work with use it all the time. FYI a 12' length on Nautique Parts is $83. Same stuff in a choice of colors is $23 on line. https://www.covebase-n-transitions.com/Johnsonite-CTA-XX-C-Carpet-to-Vinyl-Transition-Strip.html" rel="nofollow - https://www.covebase-n-transitions.com/Johnsonite-CTA-XX-C-Carpet-to-Vinyl-Transition-Strip.html ------------- Builder |

TRBenj wrote:

TRBenj wrote:

if you go with

foam (closed cell type) try to keep the hard skin which forms on the outside of

the foam as its less likely to soak up moisture.

if you go with

foam (closed cell type) try to keep the hard skin which forms on the outside of

the foam as its less likely to soak up moisture.