82 Floor Repair (I need help)

Printed From: CorrectCraftFan.com

Category: General Correct Craft Discussion

Forum Name: General Discussion

Forum Discription: Anything Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=5995

Printed Date: May-19-2024 at 4:07pm

Topic: 82 Floor Repair (I need help)

Posted By: jon4pres

Subject: 82 Floor Repair (I need help)

Date Posted: March-12-2007 at 6:17pm

|

Today I got my 82 2001 out to be reminded of the soft spot in the floor that I knew was there when I put it away for the winter.

When I bought the boat the guy told me the floors and stringers were redone in 99. It is looking to me like when they did the floors (from the start of the engine cover) back they just laid fiberglass on top of the foam. It has now cracked and is bouncy on the passengers side from the font of the motor to the back of the motor.

And as a bounus one of the mufflers was cracked

The good news is that it appears to my rookie eyes that the primary stringers look fine. I have not dug very far but also the foam seems dry and in good shape. What should I do next. My idea is to tear all of the floor up that does not have wood under it and replace it with marine plywood. Help me before I screw something up. Thanks in advance Jon ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Replies:

Posted By: 79nautique

Date Posted: March-12-2007 at 6:56pm

|

based on some of the other posts about stringers is in that area they just glassed over the foam and in your case the PO must have used very little over the foam. Does the foam seem wet? Might be able to pull the carpet grind down some of the fiberglass and build it up from there. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: SkiBum

Date Posted: March-12-2007 at 7:01pm

|

The 3rd picture indicates that there will be significant rot in the secondary stringers in that area. The foam looks good on top but gravity pulls the water to the bottom. The cracked floor means the PO did not build a strong enough floor. That breach allows water to flow into the floor. Now you have work to do.

Your idea of using plywood as a floor is fine. You will add weight. If you are not a slalom skier - no big deal. Just be sure to seal both the top and bottom of the floor pieces with epoxy before bonding them to the stringers. I would recommend removal of the foam. At least exploratory. Take out a big chunk down to the hull. If it splashes your face - its wet. From the dash to the stern the 80lb kit of foam will do the job. Dont worry about the muffler. Clean it up and use several layers of epoxy and glass as a patch. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: eric lavine

Date Posted: March-12-2007 at 7:08pm

|

the foam is always dry near the surface, chances are down closer to the hull it might be wet. Cracks are one of the reasons i prefer wood over glassing on top of the foam.

it does seem pretty thin at that area where the crack is and you may like 79 said glass over it. I think some further investigation is needed and maybe post some more pics. Its hard to believe the stringers and floors were replaced in 99, I think a little exageration was included or maybe just a bad spot was repaired. Is that carpet that wore out? or am i seeing something different Eric ------------- "the things you own will start to own you" |

Posted By: Bob's2001

Date Posted: March-12-2007 at 7:09pm

|

Jon, listen to the SkiBum and read his post http://www.correctcraftfan.com/forum/forum_posts.asp?TID=5409&PN=1 - floor and stringers . It will tell you a lot and may make you want to cry, too. I found a very similar situation in my 83 when I pulled up the carpet to check out a soft spot. ------------- Bob Ed 83 2001 |

Posted By: jon4pres

Date Posted: March-12-2007 at 8:08pm

|

Dug more and it was soaked. The secondary stringers were mush. I went ahead and tore the floor and foam out from the front of the engine back. I will post some pictures tomorrow. It is too dark and depressing out there right now. I have a feeling this could be a busy thread over the next couple of weeks. The good news is my brother is a school teacher and is off next week for spring break so I should have lots of help if the weather is good to us.

Is there a composite material that would be better to use than plywood? What about the secondary stringers?? ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 79nautique

Date Posted: March-12-2007 at 8:27pm

|

really there's no need to rehash something that has been covered pretty good on two other posts so really do we need a third started? Not saying your not as important or anything like that. It's just been covered in detail on an active thread already that's all.

There is some compsite stuff out there it's just a little pricey and heavier than other options. You might check the other threads then if something is a litttle foggy or something wasn't covered then ask and you shall recieve. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: eric lavine

Date Posted: March-12-2007 at 8:43pm

|

read up on the subject to get a better understanding of some of the materials being used.... and keep on digging ------------- "the things you own will start to own you" |

Posted By: scott8370

Date Posted: March-12-2007 at 8:55pm

Eric, You want another floor job? ------------- Scott |

Posted By: The Lake

Date Posted: March-12-2007 at 9:13pm

|

Jon,

Sorry to hear of your difficulties; that has to be dissapointing. Keep us posted as you get further into it. Hopefully the weather holds for you. Chuck ------------- Walk on Water www.coldwater.me http://correctcraftfan.com/diaries/details.asp?ID=775&sort=&pagenum=3&yrstart=1966&yrend=1970 - 69 Ski Nautique |

Posted By: jon4pres

Date Posted: March-12-2007 at 9:22pm

|

I have done alot of reading. All of Skibum's thread. Which is great. I definetly got some ideas from that.

Thanks everyone. I will try not to repeat Skibum's thread but I know I will have questions so please don't get upset if I keep asking questions. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-13-2007 at 4:52am

|

Jon4, I caught the same picture that Bill (skibum) did. Hate to say it but I think you need to keep digging. When did you buy the boat? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SkiBum

Date Posted: March-13-2007 at 9:12am

|

Based on my experiences I would simply recommend building your secondaries from pine. Laminate the individual pieces (11 total) that make up the entire stringer using epoxy resin and glass on both sides. Once bedded into the floor and glassed onto the hull they are very water proof. Just be sure to use a good bead of 404 or 403 filler as well. There may be some composites out there that will NEVER fail but whatever. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: jon4pres

Date Posted: March-13-2007 at 9:56am

|

What do you think about using composite wood. I know I have seen deck boards that are made of a composite material. I do not see any reason why I could not use these instead of pine for my secondary stringers.

I am thinking that instead of making a permanent floor on both sides of the engine compartment that I will make 2 long fiberglass tanks that I can drop in the boat. I could then fill the tanks with water for a little wakebarding weight. What I like about my idea is the ability to add weight and remove the entire floor easily without a problem. What I dont like is . . . I dont know if I can make the secondary stringers strong enough to hold these tanks. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: eric lavine

Date Posted: March-13-2007 at 11:45am

|

Jon, there is no reason why you couldnt incorporate the tanks into the structural sections of the boat, once a boat is in the water you get even stress points dispersed accross the hull of the boat, unlike the trailer where the weight would be concentrated on whatever area it is touching.

you could tie the tanks right into the stringers and struts and it would be part of the structure you really should refoam it and stay away from the composites, wood has grain and once you spend many countless hours working on the floors I doubt you will be leaving it out in the rain to fill with water or leaving it uncovered from the elements. there is no reason a boat shouldnt last 30 years after a repair with wood ------------- "the things you own will start to own you" |

Posted By: 8122pbrainard

Date Posted: March-13-2007 at 12:20pm

|

Jon, Don't even consider using the "decking" composite wood. It is made from recycled polypropelene bottles (milk bottles) and wood flour. It is also used for glue bottles because glue won't stick to it. So, epoxy resin / fiberglass won't stick ether!! It also isn't as strong and does bend. When you use it for decking material you even need to space the joists closer than you would with normal 2X material (wood). ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jon4pres

Date Posted: March-13-2007 at 1:02pm

|

Thanks guys. I will not use the composite.

Eric, What do you mean by "you really should refoam it", If I make the ballast tanks they will be in place of the foam. I want to go without the foam. I see no purpose to put foam back in the boat that is going to get wet. If I go with a plywood floor I will not need it for structure either. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: eric lavine

Date Posted: March-13-2007 at 4:15pm

|

it does provide structural support, boyancy, deadens sound..... I really dont like it but those are 3 good reasons to use it,

you cold pour it around the tanks you install and they really wont move ------------- "the things you own will start to own you" |

Posted By: jon4pres

Date Posted: March-13-2007 at 5:12pm

|

After getting home from work and realizing that everything is mush. I dont know what to do.

I am not trying to give a sob story here but I dont know what to do. I have never laid fiberglass in my life. I dont know the first thing about what I am in the middle of and most importantly I dont know how much it is going to cost but I do know that money is a little tight right now being 24 and having a wife who is still in college. Can anyone let me know around what this is going to cost. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: TRBenj

Date Posted: March-13-2007 at 6:36pm

I believe SkiBum said recently that he had spent ~$1k on all his supplies. I believe that would include gelcoat, so thats more than it would cost you. I would say a complete floor and stringer job would cost $700-1000 in materials, including carpet. ------------- |

Posted By: eric lavine

Date Posted: March-13-2007 at 6:54pm

|

expect to spend at least a $1000.00 in materials, if you use plywood expect to spend 95.00 per sheet 3/4 marine,

you could get away cheaper with out the foam, the foam with shipping is about $80.00 per kit, I used 5 kits sparringly there is alot of hidden costs as discussed in another post ------------- "the things you own will start to own you" |

Posted By: jon4pres

Date Posted: March-14-2007 at 9:41am

|

Thanks for the info. I was hoping it would be less but whats another thousand right.

Eric you are really tempting me with to not go with foam. It just seems to me tha the foam is going to get wet at some point. Plus now I find out that it is the most expensive part of the job. I guess I have a little time before I have to make that decision. I have decided that I am going to work across the floor from passenger side to the drivers. I have 90% of the flooring taken up and the secondary stringers on the passenger side are completely gone. I am leaving the drivers side in and using them as a pattern. Once I have the passengers side secondary stringers done I will move to the drivers side secondary stringers. Then I will work on the main stringers one at a time. This method seems like a good way to do it ot me because I can always go look at the other side and use it as a pattern. I still have to pull the motor but I think that I can get Dad's skid loader tonight and get that out. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-14-2007 at 9:50am

|

Jon4, There are lots of pros and cons on weather to or not foam. There was a rather involved thread on it. Do a search.

My Tique was not foamed under the floor when the stringers were redone. Foam for flotation was added on the bottom sides of the forward and rear decks as well as under the gunnels. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: nates78ski

Date Posted: March-14-2007 at 10:01am

|

Eric do you think the marine grade plywood is necessary? ive always just gotten normal plywood & coated all the edges thoroughly and put a few coats on top & bottom.

Nate ------------- Nathan http://correctcraftfan.com/diaries/details.asp?ID=1463&sort=&pagenum=3&yrstart=1978&yrend=1978" rel="nofollow - My '78 Ski Nautique <a href="http://photobucket.com/Nates78ski" rel="nofoll |

Posted By: eric lavine

Date Posted: March-14-2007 at 10:32am

|

Im not certain but was told that the only difference between normal ply and marine ply is the finish, which seems true because the ply i bought had a filler on the face and was sanded smooth, i also coated both sides and the edges. next time I'll save the money.......thats the first time i also ever used marine ply, i guess the ora is people think that it is waterproof and it isnt

Save the money for something else ------------- "the things you own will start to own you" |

Posted By: Waterdog

Date Posted: March-14-2007 at 10:44am

|

The marine 3/4 ply wood I bought has a couple more plys in it and is a lot lighter weight than other ply wood almost like bulsa wood.When I drilled holes in it the drill bit had a tar like adhesive on it. $85 a sheet but worth it. ( I think ) ------------- - waterdog - http://www.correctcraftfan.com/diaries/details.asp?ID=3896&sort=&pagenum=2&yrstart=1978&yrend=1978" rel="nofollow - 78 Ski Tique |

Posted By: The Lake

Date Posted: March-14-2007 at 10:57am

|

Marine Plywood does not have any voids in the interior plys. It's face on both sides is b grade, meaning it is sanded, can have knots, but they must be tight. The glue used is an exterior (water proof) glue. It is not treated with any preservative.

Chuck ------------- Walk on Water www.coldwater.me http://correctcraftfan.com/diaries/details.asp?ID=775&sort=&pagenum=3&yrstart=1966&yrend=1970 - 69 Ski Nautique |

Posted By: 8122pbrainard

Date Posted: March-14-2007 at 10:58am

|

Waterdog, You may have gotten a piece of Okoume marine ply. It is allot lighter than Fir ply. One thing though, It is NOT very rot resistent and is ment for epoxy saturation so make sure its coated real good. If you got it from someone who is building boats with a epoxy system, then that's probably what he had.

Eric, you're close on the marine difference. It's really the inner plys on marine that have a very tight allowence for gaps between the pieces of veneer. Otherwise both Exterior and Marine use the same phenolic based glues. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TRBenj

Date Posted: March-14-2007 at 11:48am

Remember, the newer foams are closed cell and dont absorb water like your original foam did. When I did my floor repair, I noticed the water travelled down the stringer because it wasnt being absorbed into the foam. I only removed the foam that was either detached from the hull, or in the way of my stringer repair. ------------- |

Posted By: eric lavine

Date Posted: March-14-2007 at 11:54am

|

Is it worth the extra doe? probably not if your coating both sides and edges and then painting it.

most times people are'nt coating it and waterproofing it, I have used plywoods in the past i did not coat it, up in front bunks and so on. the best thing is keeping any wood dry and it will last for years ------------- "the things you own will start to own you" |

Posted By: jon4pres

Date Posted: March-14-2007 at 11:59am

|

Even if it has closed cell foam the water is still going to be trapped under it sitting against the secondary stringers.

When it all goes back together there will be TONS of epoxy used but I am also thinking that if I go with no foam and make a removable floor then I can pull those sections of the floor out and really dry the boat out. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: boat dr

Date Posted: March-14-2007 at 12:02pm

|

Eric, i was told ,same glue same wood, the difference is the VOIDS. Marine has 0% voids,where the other designations,A/B,A/C have more or less voids.JMHO, but what do I know????? ------------- boat dr /diaries/details.asp?ID=4631 - 1949 Dart /diaries/details.asp?ID=1533 - 1964 American Skier |

Posted By: 8122pbrainard

Date Posted: March-14-2007 at 12:32pm

|

Jon4, When my Tique stringers were replaced, small have half round cutouts at stratigic locations were cut into the bottoms where it meets the floor. The cutouts were then glassed before the stringers were installed to seal them. So in therory if the water gets below the floor, it will drain to the lowest point under the engine. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SkiBum

Date Posted: March-14-2007 at 7:44pm

|

Really dont see the need to use 3/4" treated plywood for the floor. Glass would be fine. I almost used 1/8" 3ply. 1/2" normal plwood would be enough. Just apply epoxy resin, 10oz or more glass cloth, and resin to the underside before you install. Then apply two layers of epoxy resin and glass on top. When the floor attaches to the side of the hull and to the stringers it actually provides some increase in the structural integrity of the boat. There have been several clever modifications to allow water to flow out of the floor area. I am of the opinion that a properly constructed floor and stringers will seal water out. The only way it will get in is through years of neglect or acute damage.

As for cost, figre on one gallon of resin per stringer. 10yds of glass for all four stringers. Then I used five gallons on the floor as well as 30 yds of glass (10 ea Eglass cloth, epoxy mat, and biaxial mat) Good luck with your project. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 4:51am

|

Jon4, Make sure you use the "E" glass cloth with the epoxy resin just as Skibum did. It's made for it.

Did you get the engine pulled? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jon4pres

Date Posted: March-15-2007 at 8:41am

|

I did not get the engine pulled but I did start it last night just so that I would know that it made it through the winter. The oil looked black and it looks like it survived. Then I unhooked everything. The only thing left to do is take it loose at the motor mounts.

I spent a good hour driving the skid loader across town at 15 or 20 mph. My motor has two rings that come out of the motor. One on the front right and the other on the rear left of the block. I am assuming that these are made to pull the motor. Can anyone tell me any different. Where are you guys getting supplies? If you have a good online place that would be ideal because I know I wont be able to find anything local. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 9:21am

|

Jon, Take a look at this:

http://www.masepoxies.com/index.htm Yes ,the two rings are lifting points. You may ned to do some playing around if you use a short piece of chain between them to get the engine w/ tranny balanced. There are screw adjustable balancers that the pros use but they are pulling engines almost every day. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jon4pres

Date Posted: March-15-2007 at 10:43am

|

Can someone give me a shopping list. Like I said I have never touched wet fiberglass or epoxy in my life. I looked at the Pete's website and it only confuses me.

If you guys have a list of what kind and how much of everything I need it would definetly help. When I am done I will have to take all of the information that I learn and write a book "Rebuilding Stringers for DUMMIES" ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 11:39am

|

Jon, I think the best way is to take you through some steps so you don't get to far ahead of yourself. Get the floor cut out and start cutting out the old stringers. Post some pictures and we'll start talking wood. I know that Bill (skibum) is going to be your most valuable asset in this project.

You have said that you have never touched wet fiberglass before but don't worry since it isn't real hard. How are you woodworking skills? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jon4pres

Date Posted: March-15-2007 at 11:56am

|

I got the woodworker of the year award when I was in High school. That doesnt really mean anything but I am very conifident that I can do what I need to. My grandpa has a great shop full of tools that I can steal. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 12:20pm

|

Great Jon, I don't think you will not have a problem with this project. I too was Industrial Arts student of the year in high school. Of coarse that was in 1969!!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SkiBum

Date Posted: March-15-2007 at 1:04pm

|

To replace the stringers this is a pretty good list of materials:

quan item 5 gal Epoxy resin 635 thin 3:1 ratio 1 roll 50 yds 2" E-glass tape 1 roll 50 yds 4" E-glass tape 1 roll 50 yds 8" E-glass tape 5yds Epoxy mat 5qts West 404 filler (fine glass) 5qts Aerosil-Cabosil thickening agent 5qts Fairing compound 25 ea 2" wood paintbrushes 25 ea stir sticks 5 ea 1qt mixing containers 2ea 2"x10"x16' 2ea 1"x6"x12' Each stringer consumes about one gallon of epoxy resin from start to finish. Use the epoxy mat to laminate both sides of the stringers. Seat the stringers with 2 layers of epoxy mat and clamp until cured. Fill gaps with 404 filler and epoxy. Then use 2", 4", 8" strips along the joint. Use 404 and epoxy to make a bead 1" above and below the joint 1/4" to 1/2" thick. That is all it takes to laminate and install the stringers. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: jon4pres

Date Posted: March-15-2007 at 1:35pm

|

Bill, where did you order all of the fiberglassing stuff from?

I would like to go ahead and get supplies so that I have them when I need them. 25 paintbrushes?? ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: bkhallpass

Date Posted: March-15-2007 at 1:57pm

|

I remember reading that Bill ordered from US Composites.

BKH ------------- Livin' the Dream |

Posted By: TRBenj

Date Posted: March-15-2007 at 2:00pm

The paint brushes are used to apply the epoxy resin to the mat and cloth. Once it dries, theres no saving the brush, so buy a bunch. In addition to SkiBum's list, I used a grooved roller to get the air bubbles out of each layer of glass. Buy a bunch of those too. I also liked the hand pumps- makes it easy to get the right ratio of epoxy to hardener and makes less of a mess than pouring. BKH is right, go with US Composites. I guess its not really a "material" but dont forget to pick up a box of latex gloves from Home Depot. You want to keep the resin off your skin if you can. ------------- |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 2:22pm

|

Jon, You can also take a look at:

www.masepoxy.com They actually have a on-line store ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: JoeinNY

Date Posted: March-15-2007 at 2:51pm

|

For applying the epoxy, they arent worth cleaning off the epoxy after so they end up hard as a rock... a one shot deal.. you will easily use 25.

------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: JoeinNY

Date Posted: March-15-2007 at 2:52pm

|

damn that was slow typing on my part ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: 79nautique

Date Posted: March-15-2007 at 3:37pm

|

If you have a good digital scale then you can use it instead of the pumps if you want. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: 87BFN owner

Date Posted: March-15-2007 at 3:47pm

Posted By: boat dr

Date Posted: March-15-2007 at 4:12pm

|

79, You ain't going to use my Ohaus for epoxy, I have to weigh letters and such. Don't know for sure but is the ratio 2:1 by volume and not weight? Maybe I am wrong but component A and B have different weights, if so, you would use the volume method of mixing as per directions?????? ------------- boat dr /diaries/details.asp?ID=4631 - 1949 Dart /diaries/details.asp?ID=1533 - 1964 American Skier |

Posted By: 8122pbrainard

Date Posted: March-15-2007 at 4:20pm

|

It is by volume and not weight so don't use a scale!! The pumps are less than $15 and well worth it. You can mix real small 1 stroke of each pump batches plus they are allot neater since you're not pouring out of can. The pump kits fit all containers up to the 5 gal. size by using extention tubes that fit on the bottom of the pumps.

Depending on the manufacturer and the type of hardener you use, the mix ratio can vari. Read the instructions and get the proper pumps. The small batches really come in handy when you are adding fillers. The mixed volume really increases especially on the fairing fillers to the point that you sometimes can't use it fast enough before it sets up. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 79nautique

Date Posted: March-15-2007 at 5:43pm

|

I thought I recall in the instructions when I did some years ago they also listed the weights as well as volume for mix ratio's. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: SkiBum

Date Posted: March-15-2007 at 6:08pm

|

Sorry, forgot to list the pumps. Just cost a few dollars worth every penny and then some. Too easy. Pump three times move the container pump once and repeat. Also you need a good roller. I tried cleaning mine after each use but it only lasted about three stringers. Buy a few of those as well. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: boat dr

Date Posted: March-15-2007 at 11:12pm

|

79, Just pulled out direction sheet,West Systems,they have no listings of mixture by weight. The ratio is stated for use with their pumps,But you may have used a different brand..............boat dr ------------- boat dr /diaries/details.asp?ID=4631 - 1949 Dart /diaries/details.asp?ID=1533 - 1964 American Skier |

Posted By: 8122pbrainard

Date Posted: March-16-2007 at 4:17am

|

79, Some epoxy manufacturers do list the mix ratio by weight and that can be used. However it typically is used for large batches so you don't have to pump the pumps for long periods of time. The pumps are cheap and not as messy as pouring from a can but most important on small batches very accurate. One drop in a small batch will make a difference. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: eric lavine

Date Posted: March-16-2007 at 6:38am

|

you can soak the paint brushes in thinner right after each use, I used a total of 3 brushes, not mineral spirits... ------------- "the things you own will start to own you" |

Posted By: 79nautique

Date Posted: March-16-2007 at 8:23am

|

I used resin I got from the rot doctor website, liked it a little better than the west system stuff. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: scott8370

Date Posted: March-16-2007 at 8:36am

|

I use a plastic spreader and a roller. I don't see the need for epoxy resin. (cost) It's great stuff, and it certainly won't hurt to use it. Your boat wasn't made using epoxy. And once you use it, you can't go back to polyester resin in that area. I think Eric would agree, because we both use the same materials and techniques in boat repairs. You might want to remove all the bad wood and foam. Clean it up, then get an estimate.Unless you want to do the work yourself.A pro will have all the tools,and material to do the job. It may or may not be cheaper for you to do it yourself. ------------- Scott |

Posted By: jon4pres

Date Posted: March-16-2007 at 8:46am

|

I took the motor out last night. I can see where the PO tried to do some repairs. It looks like from the front motor mounts forward he tried to make everything worse. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: March-16-2007 at 8:47am

|

Jon, Pictures? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TRBenj

Date Posted: March-16-2007 at 9:24am

Are you sure? What year did CC start using epoxy? I know my '90 used AME 400 epoxy resin, and shortly thereafter (1993?) CC went to AME 5000. Regardless, the epoxy is the superior resin, correct? ------------- |

Posted By: SkiBum

Date Posted: March-16-2007 at 10:21am

|

Seems like every few weeks we have the same discussions again. This is one of them. Others include: use of foam, composite stringers, wood floors, and more.

Anyhow, the epoxy resin is more expensive. I concur. Whether or not the boat was built with epoxy or not doesn't matter. The epoxy is better than polyster for structural repairs. Vinyl Ester resin can be used over epoxy resin to allow follow on with polyester gelcote or resins. Ultimately it is your decision. Will your boat saturate with water and/or fall apart because you use polyester resin instead of epoxy? I don't think so. I used epoxy resin and a variety of glass materials and fillers in my construction. That is a technique. Take it for what it is worth. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: scott8370

Date Posted: March-16-2007 at 10:36am

Bill, your so right.I held off on my post for a couple days for that reason. There are many ways of doing a job right. And most of the four pages of techniques will get the job done . . ------------- Scott |

Posted By: jon4pres

Date Posted: March-16-2007 at 11:11am

|

Pete, I will try to take some pictures this weekend. They are pretty sad though.

------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: jon4pres

Date Posted: March-16-2007 at 5:26pm

|

I am putting my order together and have a questions?

What is fairing compound, where do I find it and what do I use it for?? ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: bkhallpass

Date Posted: March-16-2007 at 5:49pm

|

Fairing compound is for fairing - to make smooth, or aerodynamic. I believe the term comes out of aeronautics, but I'm not sure. This is why it is called a fairing on a motorcycle.

Bondo is a common fairing compound you are probably familiar with. You apply the compound and sand off to provide a smooth surface. In this case, the fairing compound is being used to form a smooth, arced surface between the right angles of your hull and the stringer. Fiberglass has trouble making a crisp 90 degree turn. By using some fairing compound to create an arched surface, you provide a rounded surface to make the transition, and avoid air gaps under the fiberglass when making the 90 degree turn. In this case, the fairing compound is resin with a thickening substance mixed in so that you can work with it and shape it. BKH ------------- Livin' the Dream |

Posted By: SkiBum

Date Posted: March-16-2007 at 8:01pm

|

Therea are a variety of fillers you can use for reinforcing, fairing, or thickening your resin. The most basic filler is talc. It is also very inexpensive. Fairing compounds can be made from talc, tiny glass bubbles, or a combination of compounds. They are available from US Composites and West Marine (more places as well-I just know of these two sources).

After I glassed in the stringers I used West 403 Micro Fibers to make a thick bead along the joint. It extended up the stringer about one inch and onto the hull one inch and it was 1/4" to 3/8" thick. I learned later I should have used West 404 filler instead. This was because the 403 is cotton and the 404 is glass which adds more strength. The use of this filler was to keep the 50-50 ratio of resin and glass for strength while bedding the stringer. When the glass work was finished there were uneven spots, layers, and print along the stringer and hull. I used fairing compound mixed with resin to fill the voids and create a flat surface. Another use for the fairing compound was when I finished glassing the floor. There were small depressions throughout. I spread the compound on the entire floor and it filled the low spots and created a very even and flat floor. I thickened some compound and put a small bead along the side of the hull and floor to increase runoff. You can use fairing compound to level, fill, and shape your work. ------------- Bill http://www.freewebs.com/billsboatworks - http://www.freewebs.com/billsboatworks www.freewebs.com/billsboatworks 1987 SN Rebuild Project |

Posted By: bkhallpass

Date Posted: March-16-2007 at 8:31pm

|

Bill, question? Does the 403/404 come premixed, or do you need to add the fibers into resin? BKH ------------- Livin' the Dream |

Posted By: 8122pbrainard

Date Posted: March-17-2007 at 7:53am

|

bk, All fillers come separate. You start with the base resin and then and then add the filler. The type of filler depends on what you are doing with it. In general, The stronger the filler the harder it is to sand so the stronger ones are used for structural and the first coat fileting.

Jon, Keep in mind that Bill was going for a glass smooth finish in his bilge that you really don't need so the fairing may not be needed. If you look at his pictures, you'll see that his bilge looks better than the outside of a Mastercraft!!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: bkhallpass

Date Posted: March-17-2007 at 9:38am

|

Thank you. BKH ------------- Livin' the Dream |

Posted By: farmer

Date Posted: March-18-2007 at 7:21pm

|

Jon,west system has two different fairing additives.407 Low-density filler and 410 Microlight.Either one can be used,and although the 410 is a little easier to sand it cannot be used on topsides or under dark colors because of temperature issues. I've found a supplier that I'm very happy with.They are Ward Marine (www.wardmarine.com) in Mass. Very competitive pricing and great to deal with. Farmer |

Posted By: jon4pres

Date Posted: April-03-2007 at 4:08pm

|

Tonight I am going to start doing something productive and not just tearing stuff up.

Bill, Eric, Pete or anyone that has done this before, will you give me a step by step guide of how to epoxy and install the stringers. Remember you can not make it to stupid for me. At this point the only thing I know about fiberglass is it is really itchy and dusty when grinded. I hope to get the first secondary stringer shaped tonight. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: eric lavine

Date Posted: April-03-2007 at 5:24pm

|

Good luck, if you run into a snag you can give me a buzz, 330-322-8817 or 330-995-4037

It really is simplier than you think, just use common sense and anything you do to reinforce the boat will be better than it has been (rotted) its probably been rotted for years and the boat hasnt cracked in half yet. one of the main reasons for those stringers are to mount your engine, the hull itself is very rigid. Eric ------------- "the things you own will start to own you" |

Posted By: dbrown

Date Posted: April-03-2007 at 6:33pm

| Has anyone had their floor and stringers professionally replaced? If so, what are we talking is a ballpark for having the repairs done? Problem is, I live in the Chicagoland area and I am tapped for space. I would have to most likely outsource the project. |

Posted By: jon4pres

Date Posted: April-04-2007 at 9:27am

|

I heard one guy on wakeworld say $3000.

It looks like I am going to spend at least $1,000-1,200 doing it myself. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: jon4pres

Date Posted: April-06-2007 at 9:55am

|

Eric, I will definetly give you a call if I need help.

I have my stringer all made and ready to install and now it is 30 degrees outside. My boat is inside but not heated and I am afraid that at that temp. the epoxy would never sit up. My stringer fits really tight to the bottom of the boat. Do I need to lay mat under the stringers or just epoxy them strait to the floor?? ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: TRBenj

Date Posted: April-06-2007 at 10:20am

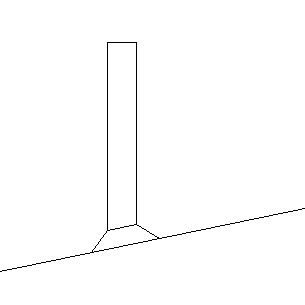

I dont believe you want the stringer to actually touch the hull. Ive read that there should be something to bed the stringer- I think SkiBum used fiberglass. Ive read of people simply placing a strip of foam under the stringer- I think this is what CC does (or at least used to do) at the factory. I actually pulled some foam out from under the stringer on my Ski Tique. I suppose most anything to create some space between the wood and hull would be fine and would prevent creating any hot spots. If you can put a chamfer on it, it will be easier to lay the glass too. Something like this:

I cant remember the recommended thickness of the bed, but Id guess 1/8"-1/4". ------------- |

Posted By: 8122pbrainard

Date Posted: April-06-2007 at 10:25am

|

Jon, I would say a layer of mat the width of and under the stringers would be helpful especially with sealing the bottom edge of the wood stringer. (lay the stringers into the mat with resin before it starts to set up) Bill (skibum) recommends this as well since it will even out any minor irregularities. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 75 Tique

Date Posted: April-06-2007 at 10:35am

Tim, So you've taken delivery on your Tique. Either I missed that or you haven't mentioned it on here. When did you get it? Obviously the delivery went fine. Sounds like you're tearing right into it. Any surprises? How is it looking? I'm trying to remember the engine situation...weren't you looking for a new engine to put into it? Larry ------------- _____________ “So, how was your weekend?” “Well, let me see…sun burn, stiff neck, screwed up back, assorted aches and pains….yup, my weekend was great, thanks for asking.” |

Posted By: jon4pres

Date Posted: April-06-2007 at 10:41am

|

Pete, I think that is a great idea.

What do you think about the temp? ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: The Lake

Date Posted: April-06-2007 at 11:11am

|

Jon,

I have done only a little fiberglass work, but I think the temp needs to be a lot closer to 80 than 30. The stuff will take forever to kick otherwise. Chuck ------------- Walk on Water www.coldwater.me http://correctcraftfan.com/diaries/details.asp?ID=775&sort=&pagenum=3&yrstart=1966&yrend=1970 - 69 Ski Nautique |

Posted By: 8122pbrainard

Date Posted: April-06-2007 at 11:43am

|

Jon, Get some heat in the garage!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: farmer

Date Posted: April-06-2007 at 12:04pm

|

I've been keeping my garage at 55F or above and the west systems 205 fast hardener sets up well. I wouldn't try to go much below that.If you are unsure, get some small quantities of whatever brand you are going to use try it in small amounts. Farmer |

Posted By: bkhallpass

Date Posted: April-06-2007 at 12:27pm

|

Jon,

I've been reading some books on stringer replacement. All recommend two layers of mat, the same width as your stringer, as a bed. Than use filling compound to take up any gaps where you stringer is not perfectly contoured to your boat. BKH ------------- Livin' the Dream |

Posted By: jon4pres

Date Posted: April-06-2007 at 2:55pm

|

Have you found a good book? I would be interested so that I didnt have to annoy everyone on here every time I have trouble. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: bkhallpass

Date Posted: April-06-2007 at 3:04pm

|

I wouldn't say I've found a good book. However, taking bits and pieces from a couple, I'm getting a better picture.

These books are written by guys that have done this type of work for many years, which is good. On the other hand, they are not "authors" by trade. Accordingly, a lot of the text is not so easy to follow. DavidF referred me to a book called The Fiberglass Boat Repair Manual by Allan H. Vaitses. It dicusses materials and application well, but much of the text is geered toward fixing big sail boats. He also referred me to a DVD called Fiberglass Repair by Will Borden. I thought it was best for showing application of gel coat. I picked up another white paper type book which is not sitting in front of me, but it was geared toward bass boats. None of these books were as desciptive about the application of the fiberglass specific to stringers as I would have liked. Actually, if you follow the two threads by SkiBum, he's just about text book. No doubt he was a little more zealous about fairing and building a smooth bildge than the experts, but his bildge does look great. The one thing I am still not clear about: Once you have put the stringer in place, in a bed of mat, and let it dry, how do you apply the glass from the hull of the boat up the side of the stringer. The bass boat guy applied tow layer of mat to the sides of the stringers before he put the stringer in. Ski Bum appears to have used a lot of overlapping 4 inch strips up the side. I'm just not sure. BKH ------------- Livin' the Dream |

Posted By: jon4pres

Date Posted: April-06-2007 at 3:44pm

|

Pete,

You dont know how bad I would like to have heat in the garage. The boat is actually in a barn and right now I am working with 200ft of extension cord just to have a trebble light and one electric power tool(more than that and it will throw the reset on the outlet). Brian, Skibum and Eric's and info from this thread are all that I have used so far. They are great and without them I would be totally lost. The problem is they are just not detailed enough, I am completly new to working on boats and fiberglass and need baby steps. When I am done with this project I owe correctcraftfan.com a major donation. Because without it I would have had to spend twice what I am to get this done by someone else. ------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: Bob's2001

Date Posted: April-07-2007 at 1:14am

|

Jon, wait til Monday & it will be warmer. It's going to be a miserable weekend in Texas, so I worked on my stringers til nearly dark and put her up til next week. I can't get mine in the garage to work on it, too much stuff. The garage WOULD be big enough if I cleaned it out, but still no heat. I wish for A/C most of the time. ------------- Bob Ed 83 2001 |

Posted By: 8122pbrainard

Date Posted: April-07-2007 at 6:56am

|

I've lucky to have my garage shop heated except for the $ but no A/C. Last summer when the heat finally penetrated through the slab, I put my box fan in the door from the A/C'd house to the garage. Worked damn good!! Didn't seem to overburden the house A/C but We don't get the "Texas" heat and humidity up here. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: farmer

Date Posted: April-07-2007 at 8:37am

|

west systems has some good instructional guides. Their "Fiberglass boat repair and maintenance" 002-550 goes into stringer repair among other things. |

Posted By: jon4pres

Date Posted: April-20-2007 at 4:38pm

|

What was I supposed to do with the Aerosil-Cabosil thickening agent?

------------- http://correctcraftfan.com/diaries/details.asp?ID=1801&yrstart=1976&yrend=1980 - 82 2001 jon4pres@gmail.com Fort Scott Kansas |

Posted By: 8122pbrainard

Date Posted: April-20-2007 at 5:00pm

|

It is a general purpose thickener. You use it for making a paste with the epoxy that can be used for filleting or filling holes. Do not use it for fairing as it is not the easyest to sand. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

jon4pres wrote:

jon4pres wrote: