Carburator - can see a lot of Gas thru air valvas

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=30062

Printed Date: May-11-2024 at 4:23pm

Topic: Carburator - can see a lot of Gas thru air valvas

Posted By: daniel1978

Subject: Carburator - can see a lot of Gas thru air valvas

Date Posted: June-01-2013 at 4:10pm

|

Mealtime! I have an 1995 Ski Nautique with PCM engine. Last year, gas ran thru the carburator into the cylinder so the starter could not start anymore because the engine stuck. I gave the boat to a local mechanic which claimed that he repaired everything. After that the boat was 2 times in the water and every time a lot of gray/black smoke, the carburator did not react on the engine idle settings at all. So I decided to get into the carburator myself and found a problem in the part which is screwd in the holley carburator first stage middle with the number 5 (I dont know the english term, however, it was not screwed in good, so the gas ran beside it directly into the motor). The Air/Gas mix was also way to fat. After that is fixed now, I need the information how to flush the engine from the liquid gas in the exhaust. I think if I dont do that, the gas in the exhaust will make a little "peng" Can I just pump in a lot of water AFTER the water pump while the engine is turned off or will the water get thru the exhaust into the cylinders? thanks for any information |

Replies:

Posted By: GlassSeeker

Date Posted: June-01-2013 at 5:08pm

|

if extra gas was pushed thru it will be in the oil, change the oil and filter and that should take care of it. unless something extremely strange has occured your worries of gas in the exhaust are unfounded=forget about it. best way to use this site is to post pictures of what you are working on and then ask any questions you want. this will help to eliminate guesswork. ------------- This is the life |

Posted By: GlassSeeker

Date Posted: June-01-2013 at 5:10pm

|

I hope you have learned that the mechanic that can repair anything is a liar. ------------- This is the life |

Posted By: GlassSeeker

Date Posted: June-01-2013 at 5:13pm

|

It also sounds a little like you may have water in the engine...gray and black smoke... need more info ------------- This is the life |

Posted By: daniel1978

Date Posted: June-02-2013 at 5:37am

|

Thank you for your replies! Since the gray and black smoke ONLY was when the boat was startet (first time everything fine if it stood a Long time) turned of and startet again an hour later (when the carbornator was complete empty of gas because it ran down into the Motor), I don not think that there is a waterproblem. also there is no water missing in the cooling System. yes, I will Change the oil, and filter - can you tell me how the pump to drain the oil is called? I have to buy one... greetings from Austria - Keep you posted |

Posted By: 8122pbrainard

Date Posted: June-02-2013 at 7:08am

|

Daniel, Check your oil pan for an oil drain hose connected at the bottom. It should have one. You put the hose through the garboard drain and the oil drains by gravity. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: daniel1978

Date Posted: June-02-2013 at 9:48am

|

8122pdbrainard, thank you for your idea. Saidly, the boat is an european Version, so there is a oilsump under the Motor wich cannot be removed (unless I remove the Motor) so I can't reach the garboard drain from inside the boat. So a pump to stick ON the oil drain hose would be fine - I saw such a pump 15 years ago by a waterski Club and want one... greetings daniel |

Posted By: SNobsessed

Date Posted: June-02-2013 at 10:03am

|

I think http://www.jamestowndistributors.com/userportal/show_product.do?pid=7729" rel="nofollow - this is what you are looking for. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: daniel1978

Date Posted: June-02-2013 at 10:40am

|

Oilremovalpump: I found it in ebay and Amazon! http://www.ebay.at/itm/110773922567?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649" rel="nofollow - ebay http://www.amazon.de/Bootskiste-Motor%C3%B6lpumpe-f%C3%BCr-den-%C3%96lwechsel/dp/B001MSGOG8/ref=sr_1_8?ie=UTF8&qid=1370172750&sr=8-8&keywords=%C3%B6lwechselpumpe" rel="nofollow - amazon |

Posted By: daniel1978

Date Posted: June-02-2013 at 3:04pm

|

Mealtime again! Still is the question, how to clean the exhaust from unused gas. I really want to to that, becaus by my last try the engine did not start but quite a big Explosion was in the exhaust so that the waterclap at the Stern was destroyed... greetings daniel |

Posted By: 8122pbrainard

Date Posted: June-02-2013 at 3:37pm

Hook the garden hose up to the exhaust manifold inlets and tilt the trailer down aft. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: leeza

Date Posted: June-03-2013 at 1:48pm

Hi,  Check this link http://www.alliancetrademarine.com I Hope this info is very useful to you Leeza ------------- Alliance Trade Marine |

Posted By: daniel1978

Date Posted: June-11-2013 at 10:11am

|

Mealtime again. Thank you for your answers. So, I changed Oil and Filter, I disassambled the carbanator again and rechecked on the workbench: everything is leakproof. So, NO gas Comes out of the carbanator on the workbench, even with a lot of pressure thru the fuel line. I put it on the engine, and started about 30 seconds. Then I can see a lot of liquid gas thru the ventilation flap. How is that possible? May it be a Problem with the electric joke? greetings daniel |

Posted By: backfoot100

Date Posted: June-11-2013 at 11:30am

|

From ventilation flap I assume you are referring to the choke plate. If you have gas dripping into the throat of the carb after you shut it down, you have one of two problems: Either the primary float is too high and needs to be adjusted down a little bit or the needle/seat set in the primary bowl is not sealing properly and letting gas past it. My bet is the float is too high. If you had it on the bench with a gas feed hooked up and pressurized and it wasn't leaking anywhere, I would say the needle/seat is OK. You need to pull the bowl off and check the float level and lower it of it's too high. ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: SNobsessed

Date Posted: June-12-2013 at 11:37am

|

Daniel - the power valve (part that was loose) can get ruptured from backfire & cause flooding. FYI. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: daniel1978

Date Posted: June-17-2013 at 4:07am

|

Hello again! Since the power valve is new and the engine did not run and did not backfire since it was installed, it can not be damaged. Yeasterday the carb was on the workbench, the needle adjustment checked, filled with gas and pressure and no gas ran out - so I dont think the Problem is there. I mean, if I give full throttle, and the air valves are open, I can see thru the carb into the engines air channel and THERE is liquid gas after a start attempt of the Motor. My theory is, that the choke valves of the Primary block do not open, so no air can geht thru the Primary carb block and liquid gas is sucked by the vaccum directly into the engine - is that possible? greetings daniel |

Posted By: daniel1978

Date Posted: June-17-2013 at 6:46am

|

The last start attempt (without choke, choke valve manually opend) was again a disaster. Relly much gas ran thru the air channel, just on single fire attempt from the engine. Where do I get a carbonator in Austria?! greetings daniel |

Posted By: backfoot100

Date Posted: June-17-2013 at 10:27am

|

Daniel, When you are pressurizing that fuel feed to the carb on the bench, how many PSI are you running it up to? You may be using a different scale there such as BAR. Do you know how much pressure the fuel pump is putting on the fuel line? You haven't changed out the fuel pump have you? ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: daniel1978

Date Posted: June-18-2013 at 1:42pm

|

Hi! I have no exact pressurelevel I put to the carb - however, the needle is new and leveled exactly like in the restore kit told from holley. No I did not Change the pump... greetings daniel |

Posted By: backfoot100

Date Posted: June-18-2013 at 4:36pm

|

If you've verified that the needle/seat isn't leaking, the float is adjusted properly, the fuel pump is not putting out too much pressure and the power valve is not blown, the only other option I would suggest is rebuild again with careful detail on cleaning and assembling. Look at this http://correctcraftfan.com/forum/forum_posts.asp?TID=30180&title=holley-issues" rel="nofollow - thread . It sounds like virtually the same issues that you have. Everything else that normally fixes this issue has not been effective. I say to get the book recommended in the thread and rebuild it yourself. They are pretty easy if you have any amount of attention to detail. ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: cphase

Date Posted: June-18-2013 at 4:48pm

Does your carb have a accelerator pump transfer tube between the metering block and the main body? You may have used the wrong gasket which can give you a rich issue because you are pulling fuel from the accelerator pump circuit. ------------- Thanks, Jeff http://www.correctcraftfan.com/diaries/details.asp?ID=6549" rel="nofollow - 82 SN http://www.archlinux.org" rel="nofollow - Arch Linux |

Posted By: gR@HaM

Date Posted: June-18-2013 at 6:25pm

And when you sort yours out Daniel you can come to England and fix mine!!  ------------- '82 Ski Tique |

Posted By: daniel1978

Date Posted: June-19-2013 at 2:14pm

|

at gR@HaM Of course! My Family and I are looking Forward to a sponsored trip to England - can we stay at your house? ;-) greetingsd aniel |

Posted By: daniel1978

Date Posted: June-19-2013 at 2:15pm

|

at cphase: Yes, it has and I double checked gasket - please read always below. greetings daniel |

Posted By: daniel1978

Date Posted: June-19-2013 at 2:17pm

|

at backfoot100: Hello! Acutally, I have two books (german of course) and disassembled and reasambled the whole Thing about 5 times now. Meanwhile ALL Fitting parts are changed 2 times, and I can not find the Problem. Please read also my next Posts... thanks daniel |

Posted By: daniel1978

Date Posted: June-19-2013 at 2:32pm

|

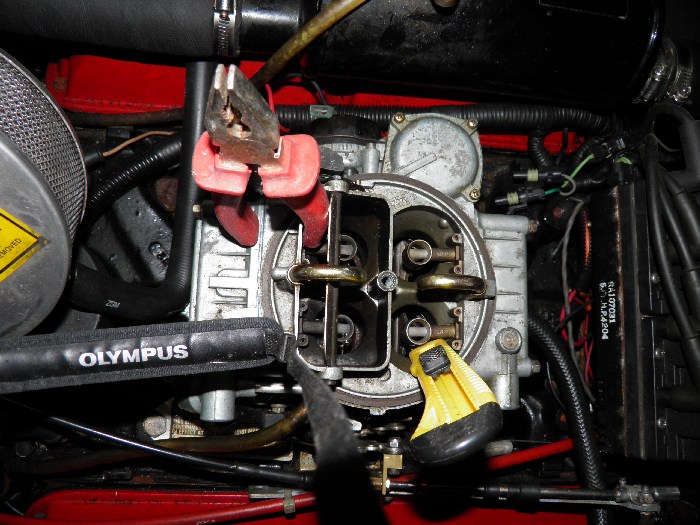

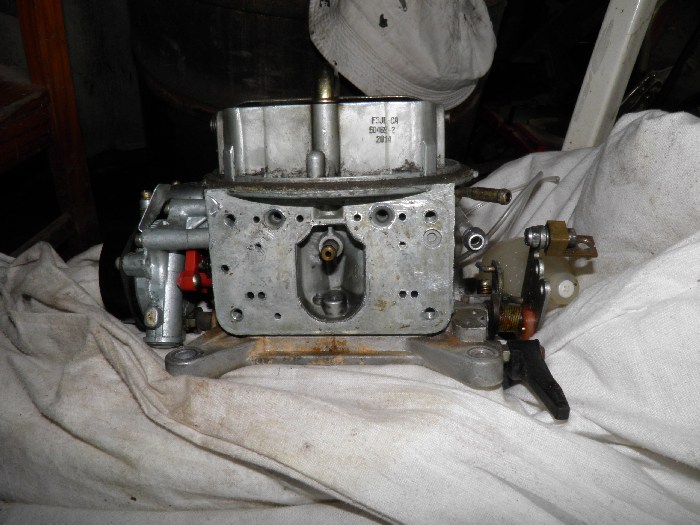

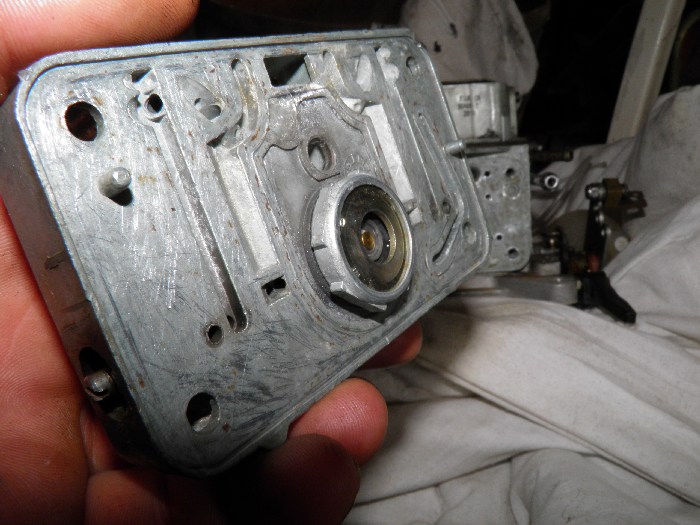

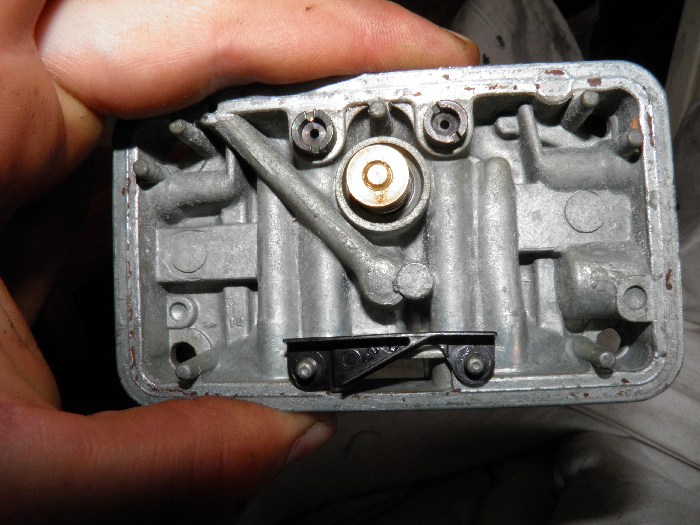

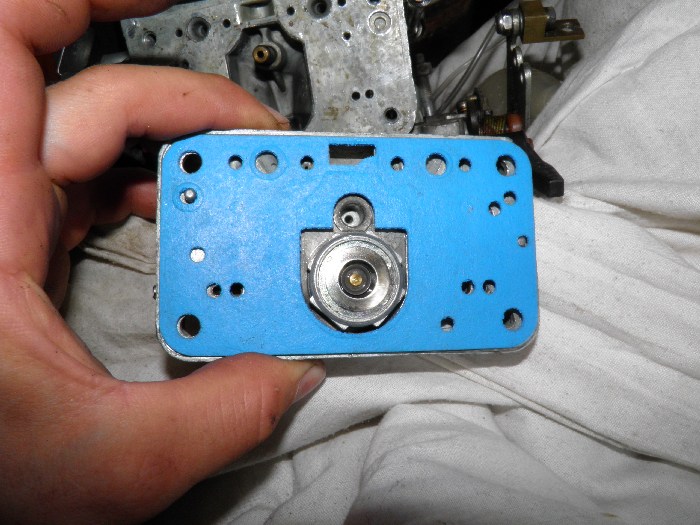

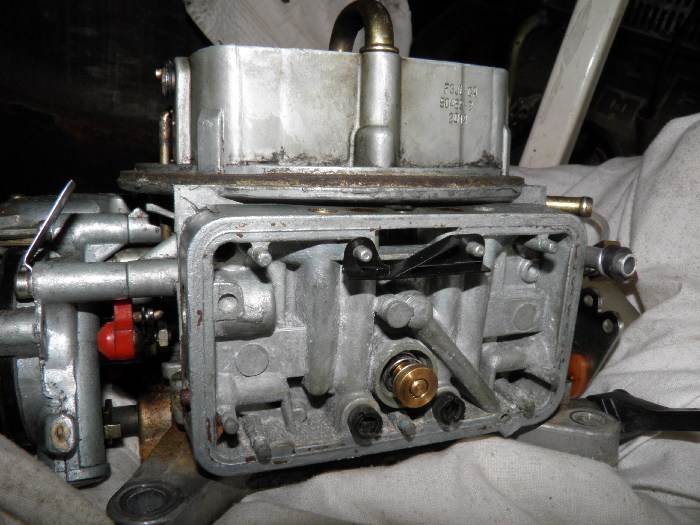

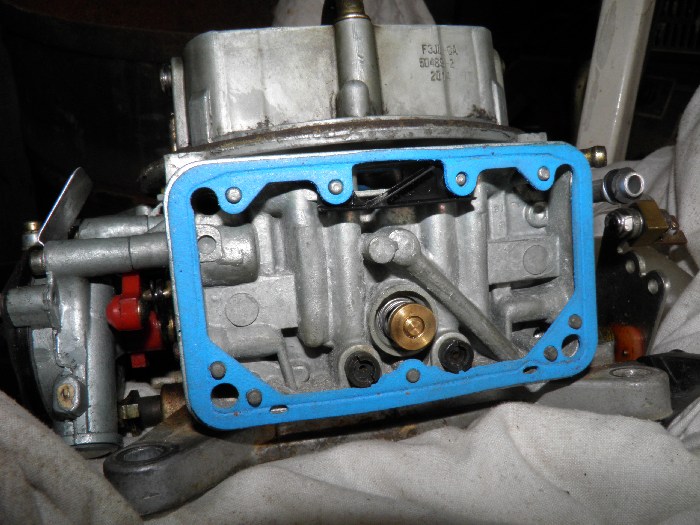

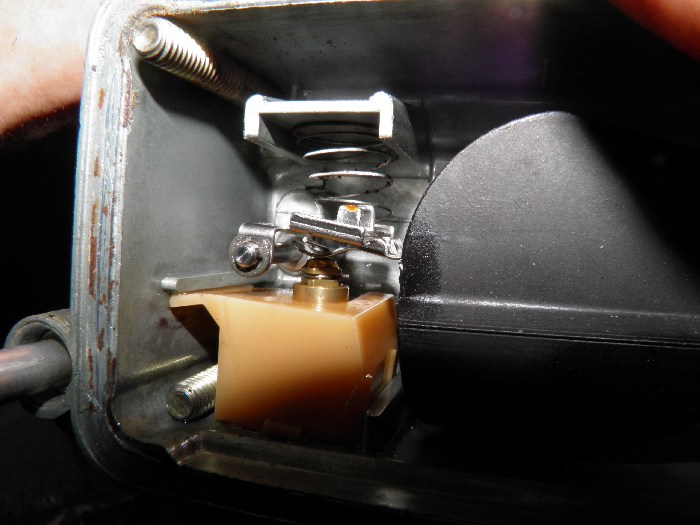

Pictures: After Start attenpt: Manual opened valve to dry everything from liquid gas  Engine Numbers:  Engine overview  Carb on Workbench - doesn't look everything fine?!         Original float Setting:   New Needle and new float Setting:   Construct to test how much pressure needlse will take bevor leaking:   please read next post for details |

Posted By: daniel1978

Date Posted: June-19-2013 at 2:44pm

|

Text: FAQ: Q: Why are there a lot of scratches on parts where gasket should be? A: Because the original gaskets really stuck on the carb. I needed several hours to scratch them of. Q: What is with the power valve and gasket? A: Both new, thightend very strong Q: Whats with the needles? A: Both new, even the old ones look exactly the same I bould a test place to check the pressure with an handpump - the carbs primary did let gas thru at ~7 psi, so I changed the float to put more pressure on the needle (lower Pictures). After that nearly 10 psi would not leak. I installed the carb and the engine was flooded with gas. So. After I started thinking again, and called a few People which Claim to know about holley carbs, I removed ALL Spark Plugs and disabled the EMS, so I can run the starter (and with it the fuel pump) without the fireresistor and no danger. I saw and wounderd: a lot of gas coming out of the Primary. I changed the float again and the Primary was fine. But the secondary flooded - so I changed that too. I run the starter again and the carb DID NOT LEAK at all. I reassambled EMS and Sparks and Plugs and tryed to start. You guess right: engine flooded! So I checked the fuel pump pressure: about 6 PSI - everything fine I think... WHAT THE HELL IS GOING WRONG HERE?! Must I really order a replacement carb? PS: maybe a colleg from carinthia will borow me another one and I can check everything else.... PPS: Is it ok to test a Car Carb on dry land if the machine is running at all? greetings daniel |

Posted By: backfoot100

Date Posted: June-19-2013 at 5:39pm

|

Daniel, I must say that you're being a trooper about this. You're finding issues and doing the right things to fix them. You've changed the needle/seats, the floats, verified fuel pressure and gone back into the carb several times. The only thing that I haven't seen you do is change the float levels. If you set the floats the way that holley recommends (flip the bowl upside doan and set the top of the float level with the top of the float bowl) which is what it looks like in a couple of your pics, the float could be too high. It's a pretty common mishap anytime somebody does a rebuild. Not usually the case with a 1:23 tranny like yours but a possibility none the less. In one of your tests with everything disconnected, you replaced the primary float and then the secondary float and had no flooding. Reassembled everything and then had flooding again. That pretty much proves that the floats were the only thing that changed and everything looked good. The float levels may have been right on that fine line of being too high and were OK for the first test and not OK the next time. When you're doing your tests with carb on the bench, the angle of the carb is probably nice and flat so everything tests out OK. When you put it back on the engine the angle is different and the floats are too high. Try to lower the float a little bit and see what happens. To answer another question, yes, it wouldn't hurt to try an auto carb for test purposes. They are jetted differently though. One with an externally adjusted float would be easier to verify float levels to be an issue. ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: daniel1978

Date Posted: June-19-2013 at 6:17pm

|

at backfoot100: Before I start writing: Thank you for your time! Since my english is not that good - especially with These specialized Terms (you see, even my Internet Explorer changes a lot of lower case to upper case letters because it thinks we are writing german), act as you write to an idiot please! I did NOT Change the float itself - i don't have them Jet and there is no gas inside even when I disassemble the carb when it is full of gas. Take a look to this photo: -) It took a while, until I realised that I have to hold the gasbowl UPSIDE DOWN to adjust - even in german books that was not clear to me. -) I am thinking UNTIL NOW that the green and blue line should be parallel after adjustment when fuel bowl is upside down -) I am thinking UNTIL NOW that the gas sould be as high as the golden metal part in normal Operation, and the float is unter liquid gas until the area where it is getting thicker (parallel to the blue line) -) UNTIL NOW I Think that to adjust the float, I simple BEND the metal between float and needle at one Point - are you saying, that I have to bend TWO Points of this metal, that the float is again parallel BUT the distance of the new parallel is larger than now? -) should I think NOW, that any other lines have to be parallel after adjustment? please enlighten me.... PS: thanks for your nice words about my repair attempts - actually it is my first Problem which I could not solve until now. And I do a lot with pinball machines from the last 50 years (my Hobby) and I even changed gears in a MAN Autobus and repaired my Ferguson 35x Traktors diesel pump... |

Posted By: cphase

Date Posted: June-19-2013 at 6:25pm

In the picture above you see the accelerator pump transfer tube sticking out of the main body. Have you pulled the tube out of the main body and changed both small "O" rings? ------------- Thanks, Jeff http://www.correctcraftfan.com/diaries/details.asp?ID=6549" rel="nofollow - 82 SN http://www.archlinux.org" rel="nofollow - Arch Linux |

Posted By: daniel1978

Date Posted: June-19-2013 at 7:51pm

| yes, both o rings are new and the tube is very hard to push in |

Posted By: backfoot100

Date Posted: June-20-2013 at 12:28pm

|

Hang in there Daniel. I think we're making a little progress now. The way that Holley recommends adjusting the float is having the bowl upside down and making the blue and green lines parallel to each other as you have so nicely drawn. You are correct. On our boats adjusting the float that way (in most cases) will cause your flooding problem. The angle of the engine (and therefore the angle of the carb) makes the fuel level higher than the float. The bowl fills up and the fuel pours out of the vent tube before the float can close the needle/seat. All you have to do is lower the float level so that it closes the needle/seat before the fuel pours out of the vent tube. You are also correct in that just bending the metal tab between the float and the needle/seat is how you would adjust it. If you have the bowl upside down as you have shown in your picture, you'll bend the tab so the float moves UP to lower the float level. I know it's confusing and our language barrier doesn't help either. If you envision how the float closes the needle/seat as the fuel level increases in the bowl, you can easliy see which way to adjust it. You're obviously a smart guy and making a lot of progress on this issue. It also doesn't have to move much either. Small adjustments make big differences. You might have to adjust a couple of times until you get it right which means making an adjustment, putting it together, trying it out and taking it apart again if it's still flooding. Also be careful of the needle/seat. They are rather delicate and can be easily damaged so try not to put any pressure on them when making the adjustments. You're doing everything right from what I can see. There should be no reason to have to buy a new carb. That one will be just fine. just be patient and we'll try and get you working again. ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: daniel1978

Date Posted: June-20-2013 at 2:10pm

|

Hello Eddie So it will be ok if the float is NOT parallel (green and blue) so the needle Closes earlier? Can you gess how big the distance of float and bowl has to be? thanks daniel |

Posted By: backfoot100

Date Posted: June-20-2013 at 2:52pm

Daniel, Yes, it's perfectly fine for the float to not be parallel (green and blue). Like I said, Holley's recommendations (parallel) are assuming you're putting the carb on a fairly level engine like an auto or truck. An application with the engine tilted back requires a lower float. As for the distance it needs to be is purely trial and error. Move the float down a few millimeters (measuring at the end of the float farthest from the needle/seat) and try it. If it doesn't stop the flooding, take it apart and move a few more millimeters. My best guess is that you should not have to drop it more than 5-8 mm total. Your transmission is a 1:23 which doesn't tilt the engine nearly as much as a 1:1. ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: daniel1978

Date Posted: June-21-2013 at 12:23pm

|

EDIT IF YOU READ TO READ THE WHOLE THREAD, read on IF YOU READ TO FIND A SOLUTION FOR A SIMULAR PROBLEM, skip and read my next post EDIT @backfoot100 alias Eddie YOU ARE MY HERO! After 1,5 year I heard my engine running Video of the first run: http://www.youtube.com/watch?v=-1bKFaKwzYE" rel="nofollow - http://www.youtube.com/watch?v=-1bKFaKwzYE In case you wonder what "er rennt, er raucht net" means: it runs! it runs! and it don't even smoke! ok, it ran only until I tried to adjust the idle Speed - but it ran! After I bent the float really hard (see Picture of primary) AND the boat stood on the Trailer in a way, that the carb is horeozental, it started. see Picture of Primary float:  Good news: -) can start engine when engine is cold -) no Explosion at all until now -) choke is moving while start attempt -) I sanded and colored the plate -) no dead children while testing -) now something changes if I turn on the idle screws (after the mechanic nothing happend and the Motor had alwas about 1200 rpm idle) bad news: -) engine can not start when block is warm -) I have no idea how to adjust the electric choke -) does not run with idle Speed lower 1000 rmp my next question is: how to adjust the choke - I could not find out with the carb Manual until now. Infos for England (you know what I mean): - pull down the float Level extreme, especually the Primary one! (you can check that your carb is not running when putting out all spark plugs and make sure there is no ignition spark (I disconnected the EMS power)and start for quite a Long time withput flame resistor while looking into the carb (no ignition no danger! BUT PUT OUT SPARK PLUGS so that the gas can not self-inflame) if no gas is there, you are on the right way - my idle adjustment with the first lucky start was full to the right an ONE turn to the left of both idle adjustments - I used NO gas at all from the throttle when the engine came to live thank you Eddie! ------------- 1995 Ski Nautique with great slanted ass. NEW: now with running engine - hurray hurray |

Posted By: GlassSeeker

Date Posted: June-21-2013 at 2:30pm

|

belt on alternator looks loose, tighten that up. ------------- This is the life |

Posted By: SNobsessed

Date Posted: June-21-2013 at 5:21pm

|

This is the type of thread that we all learn something from. Congratulations on finding the cause! ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: gR@HaM

Date Posted: June-21-2013 at 8:35pm

Yes well done Daniel, I'm planning on pulling my carb yet again this weekend, shall certainly try adjusting float height based on your findings  ------------- '82 Ski Tique |

Posted By: daniel1978

Date Posted: June-22-2013 at 3:40pm

|

So I edit my last post to give you the whole way to my solution and the steps where I had Problems: But first the video of the first (real) run after a very long time: http://www.youtube.com/watch?v=-1bKFaKwzYE" rel="nofollow - http://www.youtube.com/watch?v=-1bKFaKwzYE In case you wonder what "er rennt, er raucht net" means: it runs! it runs! and it don't even smoke! Before: The boat was not used for 2 years or so. After that, the engine did not start anymore. So I searched for a marine meachanic - not easy in Austria (there is no sea here...) and found one who claimed that he can fix my engine. He did, cashed about 550 $, destroyed my starter motor and the boat ran on the Trailer. After he drove of and half an hour later I tried to start again. It took quite a time until it came alive and there was a lot of smoke. I called him, he said he step by the next day. He came, startet and everything was fine. An hour later not so fine anymore. I decided to let it go and the boat stood a year. 2013 I tried to start again - no Chance at all. So I decided to repair myself. It was clear, that the Problem had to be the carbonator, because it was not possible to Change the idle mixture at all - always a lot of smoke in the past. I disassambled the carb and found a very interesting Thing: behind the power valve is an empty room where under pressure can pull at the valve. In this chamber are a few holes and below that holes everything was black, above silver. It turned out, that the power valve was ok, but not tightend up right. Since I was rebuilding with a repair kit I changed it and the gasket, however, the old one would work too. I put everything together (new gakets and rubber rings of course) but the engine drained every start attempt. To make a Long Story short: the Problem was the float adjustment. You have to know (Eddie told us a lot of times), that in holley and nautique Manuals the say the float has adjusted with the fuel bowl upside down and has to be parallel. That is not true at all, since in a boat the carb is not horezontal to the fuel in the fuel bowl. As well, as the secondary may work that way (since the onenings are higher becuase the carb goes down at the rear end) the Primary holes in the fuel bowl are even lower. So that is NOT always true. I tell you, better to set the float to low (especially in the primary) then to high, because to high will drain the engine - very bad Thing: oilchange, oilfilterchange, possible starter Motor destroying.... ALSO there are needles with different length from holley around. No Problem if you adjust the float so, that it will work. Also I realised: you can bend the metal part of the float (so the angle while upside down will Change) OR you can bend the small part which acutally touches the needle - so the float may NOT Change its Position upside down, but will give a different fuel Level! In my case, I bent the float really hard (see Picture of primary) AND the boat stood on the Trailer in a way, that the carb is horezontal, it started. see Picture of Primary float:  There is a way to check if the float is to high in a way, that you can not harm the boat and yourself: -) remove ALL SPARK PLUGS and cables (make sure to mark them for the right Position) -) remove the low voltage cable to the EMS in the back of the engine (you have to unsrew the securescrew) - if you have no ems, remove the whole ingition Distributor box - make sure there is NO spark at all because there could come out liquid gas from the cylinders. -) remove the airfilter from the carb -) give no throttle at all -) start (ok not start but run) with the starter Motor 4 to 6 times for 30 seconds (there is no compression now, so it will not damage the starter Motor) -) while that look in the carb from above -) if you see no gas at all: it should be fine - theoreticly - it is possible that in the water something is different because of the angle of you Trailer or ground -) if it is dry, put everything togehter - if not, adjust the float lower Then make sure to set the electric choke in the middle of the scale (see Manual for that). Set the Idle mixture screws (one left one right) fully in (to the right as far they go) and 1 or 1 and a half turn to the left (in my case 1 turn did the trick for the first start because of the next paragraph). In my Szenario also was the Problem, that the idle gas (that what you can Change where the throttle cable Comes to the carb) was way to high. In my first start attempt after the float was correct the engine drained again, because of that! If you are not sure, screw the screw out really far and give quater to half throttle to start the first time. PLEASE CHECK AT START ATTEMPT IF ANY GAS COMES OUT OF THE CARB! I destroyed a lot of gaskets from the pipe which connectes the Primary and secondary gas bowl! So remember: if your engine draines: pull down the float Level extreme, especually the Primary one! So onve again: thank you Eddie! and thank all who cared to read or write that post. As of today my engine is running fine, also the idle is now at 800 (lower as ever before) with no Problems. also do: - check belt straings and tightens - check idle mixture and Speed (to high could damage gears) greetings Daniel - will post when the boat is in the water again... ------------- 1995 Ski Nautique with great slanted ass. NEW: now with running engine - hurray hurray |

Posted By: daniel1978

Date Posted: June-23-2013 at 5:47am

|

by the way: here you can the holley 703-29 kit (whitch fits my sn) very cheep at the Moment http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=290935566894 ------------- 1995 Ski Nautique with great slanted ass. NEW: now with running engine - hurray hurray |

Posted By: 8122pbrainard

Date Posted: June-23-2013 at 8:05am

Daniel, For the convenience of all, http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=290935566894" rel="nofollow - here;s a proper link. The CCfan site does not automatically create links when you paste an address. You need to use the "post reply" and click on the world icon. The first box that shows up is where you want to put the description. Clicking OK will bring up a second box where you past the address. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KRoundy

Date Posted: June-23-2013 at 12:57pm

|

Congratulations, Daniel! Well done. Your English is better than our German, and you've left great photos and detailed instructions for everybody in the future. I'm adding this to the CCF FAQ! Let me see if my High School German courses are still working: Sehr gut mein Freund! Kevin ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: daniel1978

Date Posted: June-23-2013 at 1:33pm

|

I will do the links correct in future. Yes, your German is correct! Let me add one last Thing to my post: Do NOT Forget to Close up any hole you made in your hull to drain water BEFORE you get the boat in the lake again... greetings daniel ------------- 1995 Ski Nautique with great slanted ass. NEW: now with running engine - hurray hurray |

Posted By: SNobsessed

Date Posted: June-23-2013 at 2:09pm

Everybody does this once. It's the people who do it twice that need assistance . . . ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: backfoot100

Date Posted: June-25-2013 at 11:29am

|

Daniel, I was out of town for the weekend with no access to the site so I'm just catching up now. Glad to hear that you're up and running again.  ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: gR@HaM

Date Posted: July-08-2015 at 4:43pm

Forgot about this thread, based on that photo I can bring the float level on mine WAY down!

------------- '82 Ski Tique |

daniel1978 wrote:

daniel1978 wrote: