1997 SN Soft Floor

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=19828

Printed Date: May-25-2024 at 2:25am

Topic: 1997 SN Soft Floor

Posted By: Jones

Subject: 1997 SN Soft Floor

Date Posted: October-26-2010 at 2:53pm

|

I'm in the process of refurbishing the 1997 Ski Nautique I purchased a few months ago and have noticed some soft spots in the floor. Considering this is all-fiberglass, I thought this was a little odd. Upon removing the carpet I revealed a couple small spots that look like the floor was punctured but none larger than a quarter.

Any ideas and is it easily repairable? ------------- 1979 Ski Nautique (sold) 1997 Ski Nautique 1998 Super Sport Nautique |

Replies:

Posted By: storm34

Date Posted: October-26-2010 at 4:08pm

|

I've heard this was possibly due to dropping ski fins and other items on the floor. I've always wondered how a repair would go...I may have seen one on here a LONG time ago.

Snap some pics and show is the extent of the damage. I'd be curious to see how big of a job it would be. ------------- |

Posted By: kapla

Date Posted: October-26-2010 at 4:10pm

|

while there´s no wood as the stringers are composite..the foam is still used to fill the voids and as flotation aid..As its has foam anyway I think it over the time take water and cause the soft floor?

------------- <a href="">1992 ski nautique |

Posted By: 8122pbrainard

Date Posted: October-26-2010 at 4:17pm

|

Brad,

Yes, as Seb mentioned, the foam does support the glass floor. I'd hole saw (maybe 1") the holes out and see what's going on below. If the foam is damaged, you'll need to iject some more before you do a glass repair. Poly foams in the 2 lb. density range have a PSI rating of about 35. This is true for even the "Great Stuff" out of the can. Open it up, dig around and post some pictures. Sounds like some babe has been in that boat with high heels!!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: storm34

Date Posted: October-26-2010 at 4:22pm

|

Too funny Pete! Does anyone else remember seeing a 93+ floor repair? I'm sure Tim can tell us!

------------- |

Posted By: Jones

Date Posted: October-26-2010 at 4:27pm

|

"Great Stuff" I couldn't remember the name so thanks for refreshing my memory. I'm sure from the water infiltration and age, the original foam deteriorated somewhat. I really hate to cut a hole of any size in the floor but was thinking of drilling 3/8" and injecting foam from a can. I'll have to mull this one over.

I need to get it fixed before summer and the next round of strippers boards. ------------- 1979 Ski Nautique (sold) 1997 Ski Nautique 1998 Super Sport Nautique |

Posted By: srbranum

Date Posted: October-26-2010 at 4:29pm

Wow, a girl in the boat with high heels on.............sounds like my single days 20 years ago...yeah, I want to to see pictures too but forget the silly soft spots, let's see some party pictures!!   ------------- I have to keep her running 'cause I can't afford a new one |

Posted By: Keeganino

Date Posted: October-26-2010 at 4:57pm

I would go ahead with what Pete suggested and go bigger with a hole saw. The fiberglass repair is pretty simple and since you will be carpeting over the patch you don't have to worry about the aesthetics. It will give you piece of mind to see the damage and see that it is fixed right. ------------- "working on these old boats may not be cost effective but as it shows its what it brings into your life that matters" -Roger http://www.correctcraftfan.com/diaries/details.asp?ID=4897" rel="nofollow - 1973 Skier |

Posted By: gun-driver

Date Posted: October-26-2010 at 11:08pm

|

I say be the first one to tear the floor up in a '93 or newer (no wood) and report back with whats underneath.

You could be the father of > year'93 stringer repair. "All hail the great one" |

Posted By: Keeganino

Date Posted: October-26-2010 at 11:32pm

Thats not nice but too true! I am surprised that there is a soft spot and would like to see pics. Maybe it was just thin glass in that spot and the foam did not fill the cavity? Thats not nice but too true! I am surprised that there is a soft spot and would like to see pics. Maybe it was just thin glass in that spot and the foam did not fill the cavity? ------------- "working on these old boats may not be cost effective but as it shows its what it brings into your life that matters" -Roger http://www.correctcraftfan.com/diaries/details.asp?ID=4897" rel="nofollow - 1973 Skier |

Posted By: fanofccfan

Date Posted: October-27-2010 at 11:48am

| i have the same issue with my 96. one spot at base of passeneger seat. have not tackled it yet but am interested in what you find. |

Posted By: gun-driver

Date Posted: October-27-2010 at 11:17pm

|

Come on guys tear'em out we're all dying to know how soon we'll have to do ours.

You can be the Lewis & Clark of the no wood Nautiques. |

Posted By: mdvalant

Date Posted: October-29-2010 at 6:02pm

|

So, what is the entire floor of a later gen ski nautique made out of? Is it glass? Composite stuff?

The ski locker door on our new to us sport is made of black stuff that looks like composite trailer/boat lift bunks. Is that what the whole floor is made of? Seems very flexible when the lid is open on that ski locker. Just curious! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=5009 - '90 Ski (sold) http://www.correctcraftfan.com/diaries/details.asp?ID=5479 - '00 Sport Mississippi River - Bellevue, IA |

Posted By: TRBenj

Date Posted: October-29-2010 at 6:14pm

|

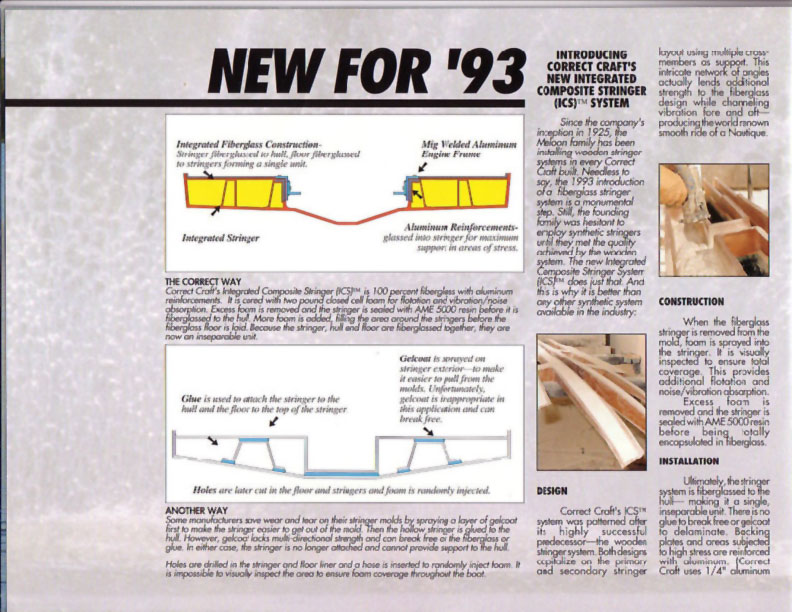

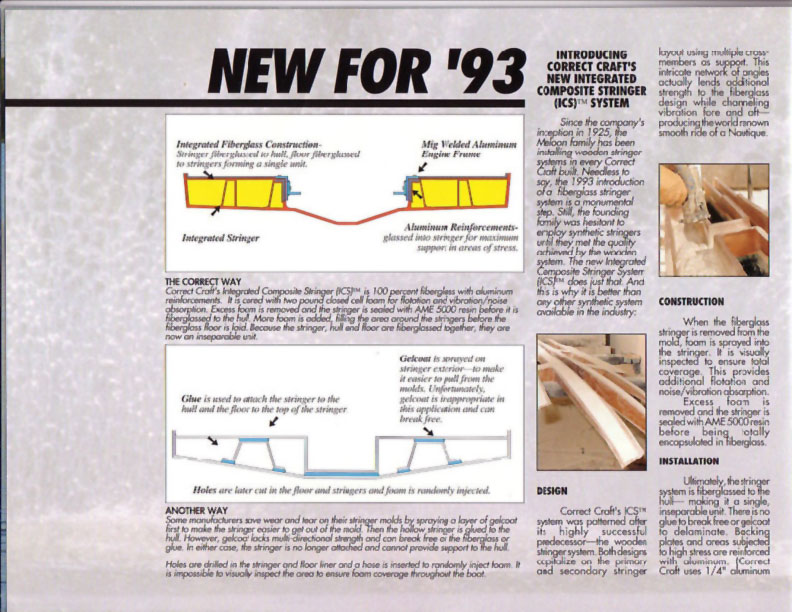

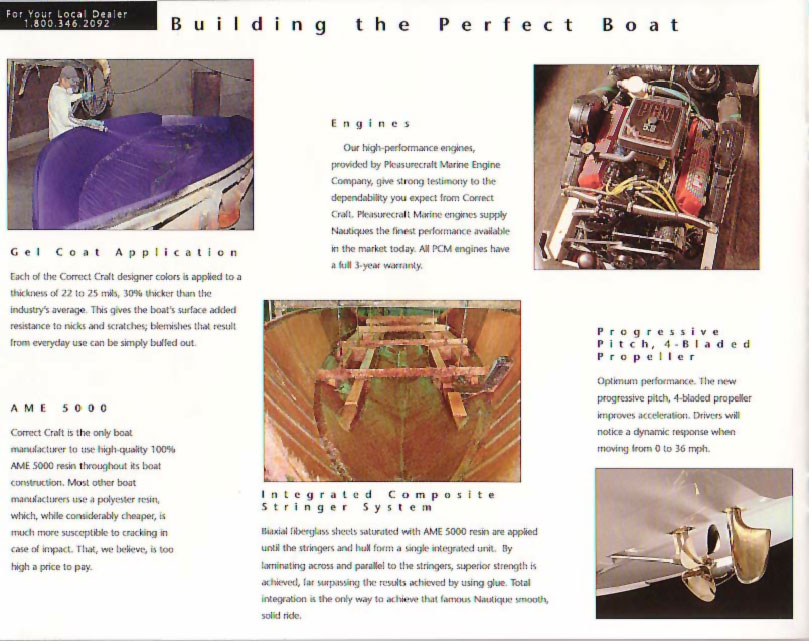

According to the '93 brochure, the floor in the composite boats is made of the same material as all of the glass boats since the late 60's... a thin layer of fiberglass on top of the foam.

http://correctcraftfan.com/reference/1993_brochure/index.asp?page=04 - 1993 brochure I would suspect that any soft spots in a composite's boat floor would be due to either an air pocket in the glass schedule, or delamination between the glass skin and the foam. The only way to find out is to cut it or grind it out. ------------- |

Posted By: BuffaloBFN

Date Posted: October-29-2010 at 6:48pm

|

So the stringers should be fine...the rest may be business as usual? ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: storm34

Date Posted: October-29-2010 at 6:54pm

|

I've always wondered if the foam would be an issue. Hopefully not in regards to rot, but weight and flotation issues. I wonder if we'll be pulling the floor and foam out of the 93+ boats in the next 10 years. ------------- |

Posted By: AussieNorts

Date Posted: August-21-2011 at 7:17am

|

Hey guys, i was reading this old thread and i have the carpet up in my 97 sport right now and have some soft spots in the floor. I am not sdure what to do, obviously some water has found its way under there and the foam has rotted a little.When i push on the area a little drop of water comes up and i see some black areas under the glass. I have attached some photos to show the floor close up and a little further away. I hope some of the experts here have some suggestions. I read in the 1993 brochure that they just drilled a hole in the floor in the factory and randomly sprayed foam. so maybe i can just inject some foam and repair the floor. What exactly to i need to use to repair the floor if i have to cut it?

------------- Correct craft.....is there any other boat? |

Posted By: 8122pbrainard

Date Posted: August-21-2011 at 7:32am

|

Steven,

It's worth a try but you know if it doesn't work, you'll have to open it up. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: AussieNorts

Date Posted: August-21-2011 at 8:19am

|

Pete, Hi again and thanks for the reply, I know about not opening it up, but do you think it is ok to cut the floor in that position? Do I just use the same matting and resin i used on the muffler to reapair the floor if i cut it? ------------- Correct craft.....is there any other boat? |

Posted By: 8122pbrainard

Date Posted: August-21-2011 at 8:23am

|

I'd just drill a couple of small holes and inject the foam. Then, yes a small glass patch. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: August-21-2011 at 8:27am

|

One more thing - the foam can create quite a lot of pressure. Inject the foam, lay a piece of plastic over the holes, cover with a piece of wood and weigh it down until it cures. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Morfoot

Date Posted: August-21-2011 at 10:46am

|

Steven, if you do decide to remove the damaged glass DON'T do it in a rectangular fashion but circular (i'm thinking maybe the size of a saucer). Once the damage is removed taper sand the edges (or bevel)and when you finished with foaming then go back with the cloth resin repair.

Using circles instead of rectangles not only makes the job easier it's a stronger repair as there aren't any corners to create a concentrated stress point and a corner is where it's going to crack first. Slightly increase the size of each ply going from smallest first to largest last with the last ply being about an 2 inches larger than the prior one. You 'll have better repair as the final layer has more parent surface to adhere to. Also with circular repairs, you won't have the corners lift up, snag on something and rip the repair off. ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

Posted By: AussieNorts

Date Posted: August-28-2011 at 9:00pm

|

Guys,

I have succumbed to curiosity and cut into the floor, after i did i was glad i chose to. Upon cutting the hole in the glass floor there was a considerable amount of water under the floor, i used a wet vac and sucked all the water i could , then i removed all foam i thought to be a little rotted or wet. I have left open the the area the help dry out for a few days, any advise from here on in? I bought a can of expandable foam from bunnings in Australia(lilke your Lowes) but i think this expandale foam may not be the best for what i want, not dense enough and not really for marine application, i think i should use the pour in foam but i have a very small are to fill like maybe two fist sizes. I have attached some pice for viewing. Please anyone with an idea as to where to go from here would be great, awaiting your replies. The hole in floor when pushed on the water coming up through the foam after i removed the foam from under the floor some foam i removed ------------- Correct craft.....is there any other boat? |

Posted By: AussieNorts

Date Posted: August-30-2011 at 10:47pm

|

Sorry to hassle guys, as I know there is a reunion going on, but does anyone have any thoughts on my next step here? ------------- Correct craft.....is there any other boat? |

Posted By: storm34

Date Posted: August-30-2011 at 11:02pm

|

If it were me, I would open up the hole to a circle as mentioned above by Tim Morfoot. Yes, this will make a bigger opening, but it will be easier to patch once you start putting everything back together.

The I'd dig down and see if there is standing water down by the hull. If there isn't, then go ahead and fill the void with two part foam (I'd get it from Jamestown Dist.) and cover it back up. ...If there's a bunch of water then you're in uncharted territory! I'd hate to hear you say there's a bunch of water because I've got a small soft spot from ski fins in our 96! ------------- |

Posted By: lewy2001

Date Posted: August-31-2011 at 12:39am

|

Steve I would make it a much larger round hole and go right down to the floor as Chris suggested.

This should give you more of an idea on the condition of the foam around the soft spot and the amount of water you have under the floor. Do those cans at Bunnings have any specs on them? ------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: AussieNorts

Date Posted: August-31-2011 at 2:12am

|

Hey Mark,

I looked on the cans but they didn`t have any specs on desity or water resistance, it actually said moisture needed to cure, so i suspect that the foam will absorb water, I am going to get pour in foam from a chandlery on Saturday. So dig all the way down to the hull hey? The foam i have dug down too seems firm and not wet but if yous think to keep digging i will, wow i hope this doesn`t turn into something huge!!! ------------- Correct craft.....is there any other boat? |

Posted By: AussieNorts

Date Posted: August-31-2011 at 2:13am

|

Also i can not make it a larger hole as there seems to be stringers either side of the current hole i have cut, if i cut wider i will cut into those, any thoughts? ------------- Correct craft.....is there any other boat? |

Posted By: lewy2001

Date Posted: August-31-2011 at 9:03am

They are fibreglass stringers so definitely do not cut into them. I would remove the foam up against them on both sides leaving the hole in the foam between them. This picture from the 93 brochure should give you an idea what is below the floor. The more I look at your previous pictures I think what happened is that something was dropped onto the floor that punctured the fiberglass skin over the foam allowing water to enter from the top. It still may be worth delving deeper but that is up to you.

------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: storm34

Date Posted: August-31-2011 at 3:05pm

|

What does everyone think of running some biaxle on the floor for additional support?

I'm planning to do carpet in the 96 at some point in the next year or two and thought it would provide some additional support to what seems like a pretty thin floor. ------------- |

Posted By: AussieNorts

Date Posted: September-02-2011 at 11:39pm

|

So I dug deeper this morning and there was more water down by the hull, i sucked it all out and then dug out the foam to the stringers on the sides and forward and back till I hit a cross member. There water seemed to be contained to that compartment as I dug next the the cross member and there was no water.

So I am thinking I will let this dry out and then pour the foam and patch up, you think I am doing this right guys? Sure do not want to have to go back down there to fix anything. Steve ------------- Correct craft.....is there any other boat? |

Posted By: Morfoot

Date Posted: September-03-2011 at 11:10am

|

Steve, I think you're on the right track. Glad you took the advice here and dug deeper. Has any more water seeped through the foam as it sits? Is the new foam pourable I guess? If not then you could always cram pieces of those 'pool noodles' in there and fill the gap with the foam in a can.

I'd work on the hole you cut into a form it to more of an oval shape and then bevel the edges so when you lay down your new glass you have a simple shape to follow and so the repair will lay down into the removed portion like a 'plug'. ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

Posted By: AussieNorts

Date Posted: September-05-2011 at 1:53am

|

Tim,

No more water seems ed seep from the foam, I have dug forward and aft of the hole as far as I can, seem to have hit some cross members. I noticed a little moisture the next morning, I just vac it up and then hit the area with heat gun for about ten minutes, I am going to keep the area open to air out for at least 5 days. Then I am going to pour the foam and patch, hope this is all good as I want to get the new carpet in. ------------- Correct craft.....is there any other boat? |

Posted By: KRoundy

Date Posted: September-06-2011 at 12:44am

|

Sounds good. Keep us informed as you progress. Keep posting pictures for those of us learning as you go. :) ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: AussieNorts

Date Posted: September-11-2011 at 7:29am

|

Guys,

Well I have finally had to look further under the floor as there was still some water there seeping through the foam. I have cut holes along the main stringer between it and the secondary. F}Refer to this picture of the two holes. The next images show down under the floor at the ends where i have dug out the foam right o=up to the `crossmembers` (sorry not sure what else to call them, they seem to rum between the main and secoudary. Anyway down under there where the water has been sitting it has penetrated the glass, I have delamination on part of one cross member, the glass has has soften in areas under there. I am not sure what to do now. I hope masters with the knowledge here would like to chime in. Here are the other pics. I hope the pics explain a little of what i am going through, not very good at the moment, I am going to seek some help, I think the repairs are now going to be major right? ------------- Correct craft.....is there any other boat? |

Posted By: SNobsessed

Date Posted: September-11-2011 at 10:24am

|

Steven - Good thing you don't have wood stringers!

You can just grind the delamination & build the glass back up to thickness. This is an example of how a snall spot on the surface can lead to a big mess underneath. Good luck ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: lewy2001

Date Posted: September-11-2011 at 10:54am

|

Steve I cant see the delamination clearly in those pictures I can see what appears to be a air bubble in the original layup around what you are calling "cross members". Just grind that out and any other soft parts around it. Then re apply some more resin and matt.

You have probably dug in deeper than you wanted to already with our season approaching fast. I guess you could remove the complete floor and foam but I would be closing up (Do a tool count first  ) and sending the patient to recover in a warm enviroment. Bring on summer ) and sending the patient to recover in a warm enviroment. Bring on summer  ------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: Liledgy

Date Posted: September-11-2011 at 12:10pm

| Great pics, and +1 on the wooden stringers. |

Posted By: Morfoot

Date Posted: September-11-2011 at 8:06pm

|

I 2nd on Chris suggestion. Remove the delam removing minimal material in a circular pattern by taper sanding as best as you can. Tap test the area with a heavy coin or end of a folded up pocket knife to be sure you've got it all. A dull thud means you still have delam in there. layer up the repair with the smallest ply first then get bigger as you go over lapping the prior one. Doing this ensures multiple layers adhering to the hull instead of just one.

Lewy looks to me like it's the "egg" or "pimple" in the picture is his delamination. ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

Posted By: AussieNorts

Date Posted: September-11-2011 at 8:52pm

|

Where the `egg or pimple` as you mention is in these picture is where i noticed mooisture under the glass. I have to post another picture showing the delamination better. I hope this is all i need to do, if the water has gotten underneath the `crossmembers` where else would it have gotten into. I hope these pics help anyone with soft floor in a 93+ boat. There can be trouble under there. I will take some more pics and post tonight when i get home. Thanks again for all the input on here guys i truly appreciate it.

I have pulled my windshield apart and had it all powder coated at my work, came up great!! I am having trouble sourcing new screws for the windshield I have taken some pics of the screw:

Does anyone here think they could help me source these screws in black, neally impossible for me to source in Australia. I hope someone can help me. I will post tonight when home guys. ------------- Correct craft.....is there any other boat? |

Posted By: AussieNorts

Date Posted: September-12-2011 at 7:50am

|

OK So i have taken a couple more pics for you to show the delamination, what I have taken today is the other side of the cross member, in the smaller hole in the first picture i posted of the floor. This are is delaminated alot worse than in the other hole towards the stern. This area has a small hole i suppose under the cross member that i have shown by sticking my finger into.

Hope these make it clearer: Thankyou again for all the help and comments on here you guys are great, well I hope i only still have to grind off the bad material and re lay I should use epoxy mat and resin to do this? Thanks again Steve ------------- Correct craft.....is there any other boat? |

Posted By: BuffaloBFN

Date Posted: September-12-2011 at 5:10pm

|

Yes on the epoxy.

Going on Mark's(Lewy) comments, I'd button it up as well. Then you can plan for next winter because a floor/stringer project sucks when every day is nicer than the last, and it's not a project that lends itself to being in a hurry. Are the stringers sound? And if you do button it up, it'll be interesting to see if you have a list. ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: KRoundy

Date Posted: September-12-2011 at 6:22pm

|

Maybe it is just me, but is that really delamination? Or, is that an area you cut out? I am just wondering where the material went. I see fibers lying there, but that's the way things look from a cut-gun I think. Is the area "soft" or does it just look bad. What does the tap-test tell you is going on?

You are making me weak in the knees. I sure hope that I don't have to do this to my 1993 Ski. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: storm34

Date Posted: September-12-2011 at 6:37pm

|

Kevin, I'm in the same situation as you on this topic and have been following closely. I'm sure many fins have been dropped on our floor creating soft spots in high traffic places. My plan is to do as listed above for the entire floor, then refoam and use glass, mat and Biax.

I'll wait a few years till we need to replace carpet but would like to weigh the boat in the mean time to see if she's overweight. ------------- |

Posted By: KRoundy

Date Posted: September-12-2011 at 8:16pm

storm34, any idea what should a naked 1993 Ski Nautique hull should weigh? My carpet is out now, so if I'm going to do this now is the time. I'd rather not tear out the floor, but these photos have me rethinking my strategy. I got a 1993 because I didn't want to do a huge fiberglass job.

------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: AussieNorts

Date Posted: September-13-2011 at 1:08am

|

Kevin,

I have not removed any material other than the foam, the matt may have been roughed up a bit when removing the foam but not that much. I believe the glass has deterioated due to the moisture. The area is not soft I have not done the tap test as yet. I believe i will just sand back to good material and re matt and glass, pour the foam and get the hell out of there!!!! You are so right Mark I just want to take it to the lake!!! Mark I have mentioned before that my partners family are all from Tamworth, I believe we are meant to come down for christmas , maybe we could catch up. Was thinking of putting the boat on a train down there so I can go ride on keepit. ------------- Correct craft.....is there any other boat? |

Posted By: KRoundy

Date Posted: September-13-2011 at 3:13am

|

Well crud. I'm glad that you are paving the way for me.

http://www.correctcraftfan.com/forum/forum_posts.asp?TID=23485&PID=295649#295649 - Rough 1993 Ski soft floor I have some new questions: 1. How do you know the rest of your foam isn't wet where you have not cut out the floor? 2. What are you using to cut out the floor? I did my small cut with a razor blade, but that's not a process that will work for much more than a small area. 3. I notice that you are not cutting out the floor on top of the stringers. I agree with this concept since the floor is attached to the top of the stringer. How are you going to lay down fiberglass in those holes you have cut and "reattach"? 4. Those of your suggesting "sanding in", what type of sanding are you talking about? Is this sandpaper? A tool of some sort? That's enough questions for now. I'm going to go get a beer and wait for replies. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: KRoundy

Date Posted: September-13-2011 at 3:20am

Oh, and I think I have a source for those screws! Let me have a look for you and I'll let you know. I know exactly which screws you are talking about. I have a labeled baggie full of them.  ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: AussieNorts

Date Posted: September-13-2011 at 4:30am

|

I have done some small cuts on the starboard side and there seems to be no moisture, but I would have to dig to the hull again to be sure, do not think i will be doing that before summer. I used a diamond tipped continious rim cutting blade for my grinder. I have to `taper the edges of the holes alot more yet then i will use strand and epoxy resin. Based on what i know and information here i just `step up each layer up the taper` applying approx 7 layers of strand with resin. I hope that is right. The sanding comment i am not too sure about, i think i would need to grind those areas just not sure if i will be able to get my grinder into there, a dremel would probably be better.

Really Kevin?, you think you can source new screws in black for me? You would be a lifesaver!! What about the rubber seal that was under the windshield any thoughts on where to get that, I have sourced most parts from Taylormade in Australia or US but the screws and that seal are nowwhere to be found. I read on here a thread about using powdercoat or not on windshields, well i have just done mine at my factory down our paintline. My operator told me that it needed to be epoxy primed first before the powdercoat, she did that and they all look great. I had them sandblasted first. I also did the vents under the windshield and the tower, all look amazing. I will post pics if anyone is interested in seeing the powdercoat, They are not on the boat yet. ------------- Correct craft.....is there any other boat? |

Posted By: BuffaloBFN

Date Posted: September-13-2011 at 9:20am

I suspect that is an area that wasn't rolled out well in the first place. Note the foam that's 'under' the glass. All of that nastiness has to go away for new material to stick. ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: KRoundy

Date Posted: September-15-2011 at 2:39am

|

Here's another question. WHAT are those cross-member pieces? Those vertical walls all are structural pieces. I'm just surprised to see that they go fore-aft as well as side-to-side.

Does anybody have something akin to a structural diagram for a Ski Nautique in the composite era? I hope to go shopping for black screws tomorrow, but I need to know: Where did these screws come from? The smaller ones are for the windshield frame, right? Are the larger ones the screws that go into the hull? And - sorry, but I do not have source for new rubber seals. Email me directly at kevin dot roundhill at gmail dot com. Kevin ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: Hollywood

Date Posted: September-15-2011 at 12:49pm

|

Those screws look pretty basic, you can't find them on McMasterCarr's website? ------------- |

Posted By: 8122pbrainard

Date Posted: September-15-2011 at 12:57pm

http://www.mcmaster.com/#tapping-screws/=e2mvj9 - black oxide 18-8 stainless screws at McMaster Go to "pan head phillips" and scroll down the page. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KRoundy

Date Posted: September-29-2011 at 4:27pm

|

How do you know what screw size that we have? ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: kapla

Date Posted: September-29-2011 at 4:32pm

hours and hours in front the screen reading CCF!  ------------- <a href="">1992 ski nautique |

Posted By: 8122pbrainard

Date Posted: September-29-2011 at 5:03pm

By measuring the diameter. McMaster will have a chart showing the size of #6, #8, #10, etc. But, here it is!! #6 is .138" #8 is .164" #10 is .190" ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: eric lavine

Date Posted: September-30-2011 at 9:54am

|

isolated case? ------------- "the things you own will start to own you" |

Posted By: Luchog

Date Posted: September-30-2011 at 11:38am

|

and those with the composite hulls shall fear... water again!!! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2095" rel="nofollow - 1980 Ski Nautique Commander 351W |

Posted By: kapla

Date Posted: September-30-2011 at 2:25pm

|

I would think added weight is the only problem in a composite hull? or is there other concern? like water will rot something? will the glass loose strenght?

If you are a skier might concern the weigth thing as being heavier might affect the wake size! but as a wakeboarder It would be a plus!!! only donwside is the increased fuel consumption... ------------- <a href="">1992 ski nautique |

Posted By: mdvalant

Date Posted: September-30-2011 at 3:21pm

|

Has anyone ever thought of placing a really fine screen about 1/4" off the hull and then laying foam on top? Then you could possible add some drain holes through the stringers to get the water out/let it drain? I guess those drain holes would then fill up from the bilge though...hmm.

I remember Chris Mars talking about how interesting it'll be in a couple years (a couple years ago) when we have people starting to tear up the composite boats. Thought it'd be a lot farther down the road than it has been. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=5009 - '90 Ski (sold) http://www.correctcraftfan.com/diaries/details.asp?ID=5479 - '00 Sport Mississippi River - Bellevue, IA |

Posted By: TRBenj

Date Posted: September-30-2011 at 3:28pm

Like Joe said, if the foam does soak up water, its not likely to drain itself- so leaving a space for it to go is sort of a pointless effort. Not to mention that its more likely to introduce water to the foam than it is to keep it dry. If youre going to foam a boat, then I contend that you need to make a very good effort to make sure that no water ever gets into the structure. Better yet, just leave it out... it'll cost you more (time and materials) but its not hard to replace the strength of the foam by adding additional support members. Replacing the buoyancy of the foam is another issue, but Pete has mentioned that spray foam can be added under the gunnels. ------------- |

Posted By: storm34

Date Posted: September-30-2011 at 3:49pm

I still like the idea of putting down thick plastic and then pouring in the foam and sealing it on top. Almost like the drug smugglers do when they pack up a shipment!

I guess if your boat was ever impounded it would be a little suspicious! ------------- |

Posted By: Nevergrew

Date Posted: September-30-2011 at 8:32pm

Ignorance is bliss I say

Until my foot falls through the floor of my boat I won't be doing a thing to it

|

Posted By: KRoundy

Date Posted: September-30-2011 at 10:14pm

|

What is meant by "adding additional support members"? Any pictures of what that means? I type this as I'm in the midst of digging out soaked foam from my boat.

Kevin ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: eric lavine

Date Posted: October-01-2011 at 10:46am

|

Tim, havn't you learned its a losing battle.

we have yet to hear someone tear into these boats and find nice dry foam, its the zig of the zag, funny thing is to on cars or trucks, anywhere you find foam to keep the panels from rattling...thats where the car is rotted ------------- "the things you own will start to own you" |

Posted By: Luchog

Date Posted: October-01-2011 at 5:14pm

Eric can you install a RH engine on a car? or it would take the car off balance???  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2095" rel="nofollow - 1980 Ski Nautique Commander 351W |

Posted By: KRoundy

Date Posted: October-02-2011 at 3:51am

|

Aussie,

Is your floor always the same thickness? I've discovered that my floor is not just a thin cap of fiberglass, but appears to be an engineered structure with cross members and varying thicknesses. Just curious to see what you have exactly found as you cut into things. I'm beginning to wonder about the "ignorance is bliss" idea myself. I feel compelled to dig around and find all the water I can find, but wish that I didn't have to do so. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: AussieNorts

Date Posted: October-02-2011 at 8:58pm

|

Kevin,

Yes the small areas I have cut out seemed to be the same thickness. I have not noticced what you are talking about, but if you refer to my pictures, I believe i have cut out in a different area to yourself. I have not cut into the floor aft of the motor area, just minly to the port side of the bilge area. Mate I know there will probably be water on the starboard side but I am just going to ignore for the time being, maybe next winter I will tear into it, but for know we have summer fast approaching!!! I need to button it up and get the new carpet and motor in. I will have a look at McMasters for the screws. I hope thay send to Australia, if not I may take you up on that offer to send them to me, thanks Kevin. Steve ------------- Correct craft.....is there any other boat? |

Posted By: TRBenj

Date Posted: October-03-2011 at 12:46pm

Our BFN:

------------- |

Posted By: KRoundy

Date Posted: October-03-2011 at 2:18pm

|

Ah. That's what I thought. Are those wood? ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: TRBenj

Date Posted: October-03-2011 at 2:22pm

|

No, we rebuilt the BFN with composite (coosa). ------------- |

Posted By: lewy2001

Date Posted: October-28-2011 at 1:27am

|

Posted this more for information on what is below the floors in no timber stringer boats from 93 onwards. From the brochures in the reference section you can see that from 1993 they had a ICS fibreglass stinger layout very close to the old wooden stringers.

This layout appears to have been continued up till 1997 as the brochures show a jig placing the stingers in the hull for layup. While browsing the 98 brochure the other night I found a totally different stringer layout in the colors section of the brochure. 1993 Brochure

1997 Brochure

1998 Brochure  ------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: eric lavine

Date Posted: October-28-2011 at 9:43am

|

i got pics of a floorless 95 with the striger layout, need to load them ------------- "the things you own will start to own you" |

Posted By: eric lavine

Date Posted: October-28-2011 at 9:45am

|

Tim, did Kurt call you on the ski pole pocket? I wasnt sure how the BFN's held them in without a cradle...if you have a pic... ------------- "the things you own will start to own you" |

Posted By: TRBenj

Date Posted: October-28-2011 at 11:08am

Nope, no call to me. The early non-cradled BFN's pylons were held in with 2 things: 1) the 1" pin at the bottom of the pylon was inserted into a cup fiberglassed to the hull 2) There was a square flange welded to the pylon at the floor, 4 bolts and a backer plate sandwiched the floor. You can see how our '79 was set up in our rebuild thread. We put it back the same way it came from the factory- except for the addition of the cradle. ------------- |

Posted By: storm34

Date Posted: October-28-2011 at 1:27pm

Eric, I'd love to see those! ------------- |

Posted By: KRoundy

Date Posted: October-28-2011 at 3:02pm

|

Me too. Go, Ed, Go!

Kevin ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: eric lavine

Date Posted: October-28-2011 at 11:53pm

|

consider it done, sometime in the near future ------------- "the things you own will start to own you" |

8122pbrainard wrote:

8122pbrainard wrote: